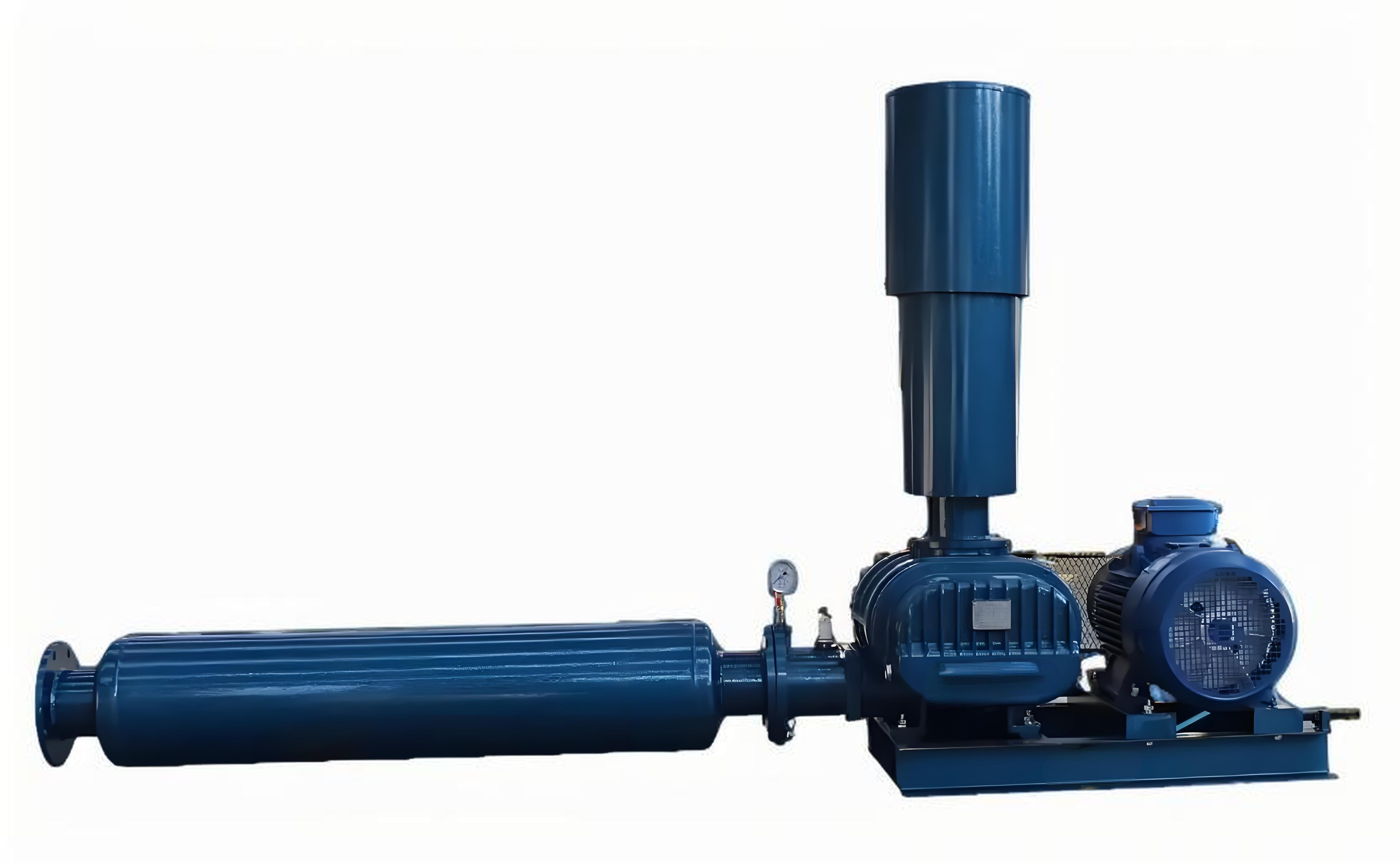

mukautettu juurilaskuri superkaiutin

Mukautettu roots-tyyppinen supercharger edustaa pakkoiltoilmenneyden teknologian huippua, suunniteltuna toimimaan ylipäätään paremman ilmakehityksen tuottamiseksi parantamaan moottorin suorituskykyä. Tämä mekaaninen supercharger koostuu kahdesta vastakkain pyörivästä lopusta, jotka kytketvät ja tiivistävät ilmaa ennen kuin se pakotetaan moottorin inkaukseen. Erilaistuen perinteisiin supercharge-reitseihin, mukautettu roots-tyyppinen versio tarjoaa mukautettuja määrittymiä täyttääkseen tiettyjä suorituskykyvaatimuksia ja moottorikonfiguraatioita. Järjestelmä toimii käyttämällä tarkasti puolittuja rotorit, jotka luovat ilmapussit loppien ja kappaleen välille, tehokkaasti lisäämällä ilman tiheyttä ja tilavuutta, jonka moottori saa. Mitä erottaa mukautetun version muista on sen kyky muokata loppien suunnittelun, hampurisuhteiden ja kappaleen mittojen osalta optimoidakseen suorituskykyä erityissovelluksiin. Teknologia sisältää edistyksellisiä materiaaleja ja peitto-prosesseja varmistamaan kestovuus ja tehokkuus, kun taas moderneja valmistustekniikoita käytetään saadakseen tarkat toleranssit ja paraneet sulkemisominaisuudet. Nämä superchargerit ovat erityisen arvokkaita korkeasuorituskykyisissä autoliikenteessä, teollisuuden ilmanjakelujärjestelmissä ja erikoismekanismeissa, joissa tarkka ilmajakelu on ratkaisevan tärkeää. Mukauttaminsoptiot laajenevat ajosysteemiin, mahdollistamalla erilaiset radan suhteet ja viemälän konfiguraatiot saavuttaakseen halutut boost-tasot ja kytkentäominaisuudet.