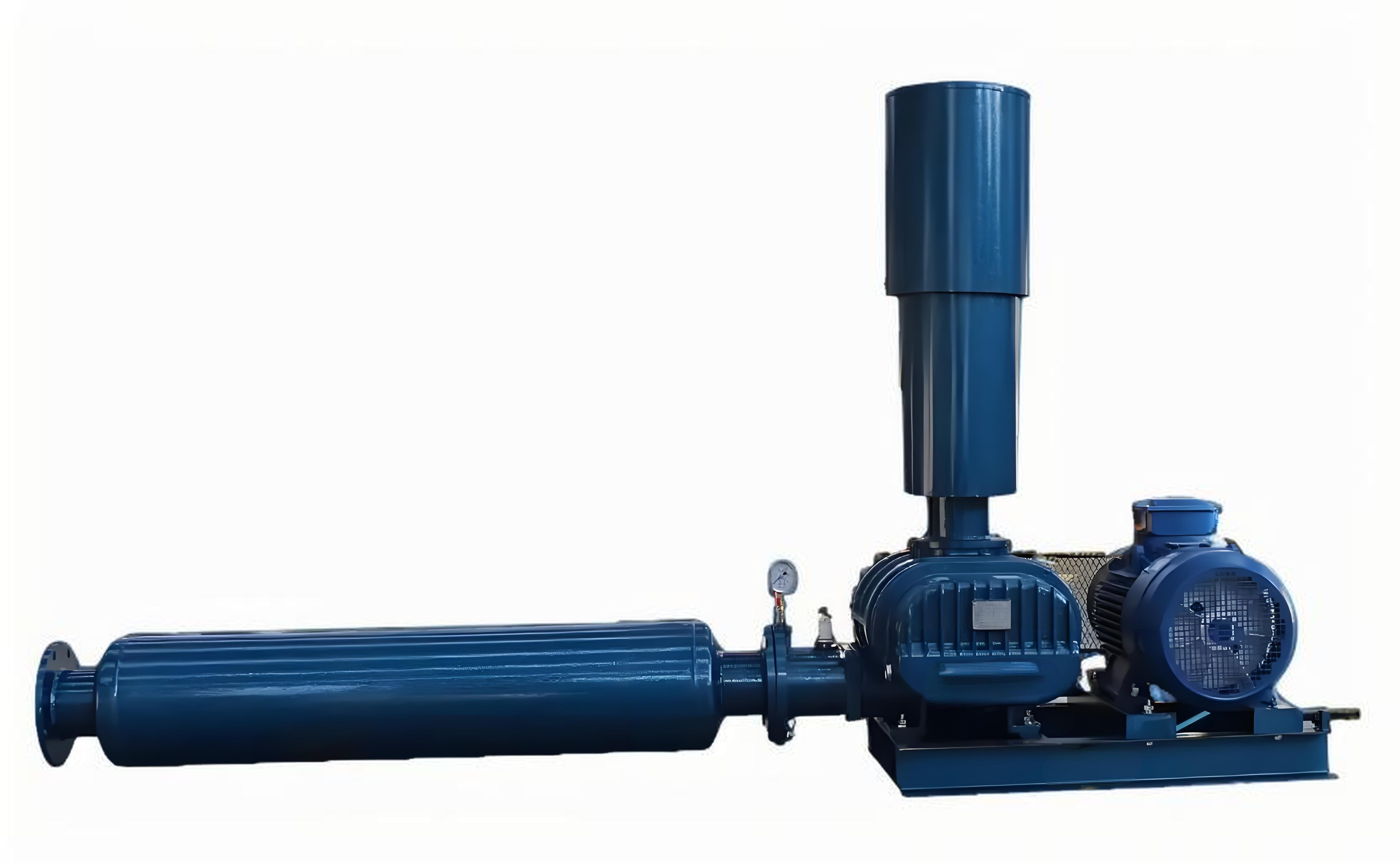

advanced roots blower supercharger

The advanced roots blower supercharger represents a significant evolution in forced induction technology, delivering exceptional performance and reliability in various applications. This mechanical supercharger consists of two counter-rotating lobes that trap and compress air before forcing it into the engine's intake manifold. The precision-engineered rotors feature advanced coating technologies and optimized profiles that minimize internal friction while maximizing airflow efficiency. Operating through a belt-driven system connected to the engine's crankshaft, the roots blower provides instant throttle response and consistent power delivery across the entire RPM range. The modern design incorporates sophisticated timing gears and precision bearings that ensure smooth operation and reduced noise levels compared to traditional superchargers. These units are particularly notable for their ability to provide significant power gains at lower engine speeds, making them ideal for both performance and industrial applications. The advanced thermal management systems and integrated intercooling capabilities help maintain optimal air charge temperatures, contributing to improved engine efficiency and reduced stress on components. With robust construction using aerospace-grade materials, these superchargers offer exceptional durability and consistent performance under demanding conditions.