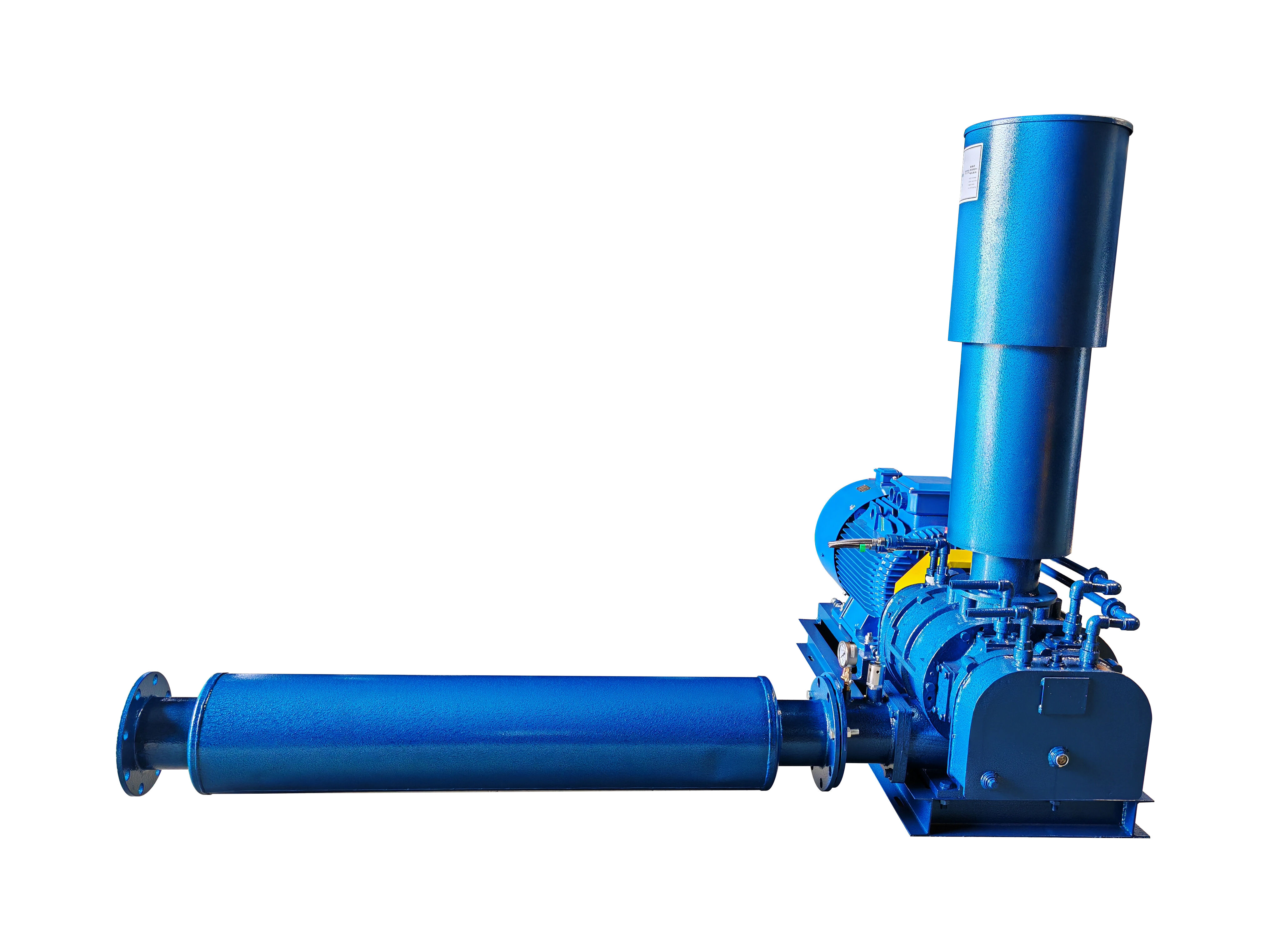

small roots blower

A small roots blower is a precision engineered mechanical device that efficiently moves air or gas through a system using a unique rotary displacement method. This compact yet powerful machine consists of two figure eight shaped rotors that rotate in opposite directions within a specially designed housing, creating a continuous flow of air or gas. Operating on the positive displacement principle, these blowers are designed to maintain consistent pressure and flow rates across various operating conditions. The device features precision machined components, including hardened steel rotors, high quality bearings, and specialized sealing systems that ensure optimal performance and longevity. Small roots blowers are particularly valuable in applications requiring reliable, oil free air or gas compression at moderate pressure levels. They excel in both industrial and commercial settings, providing essential air and gas movement for processes such as wastewater treatment, pneumatic conveying, and various manufacturing operations. The blower's compact design makes it ideal for installations where space is limited, while its robust construction ensures reliable operation even in demanding environments. Modern small roots blowers often incorporate advanced features such as variable speed drives, noise reduction technology, and efficient cooling systems, making them both versatile and energy efficient.