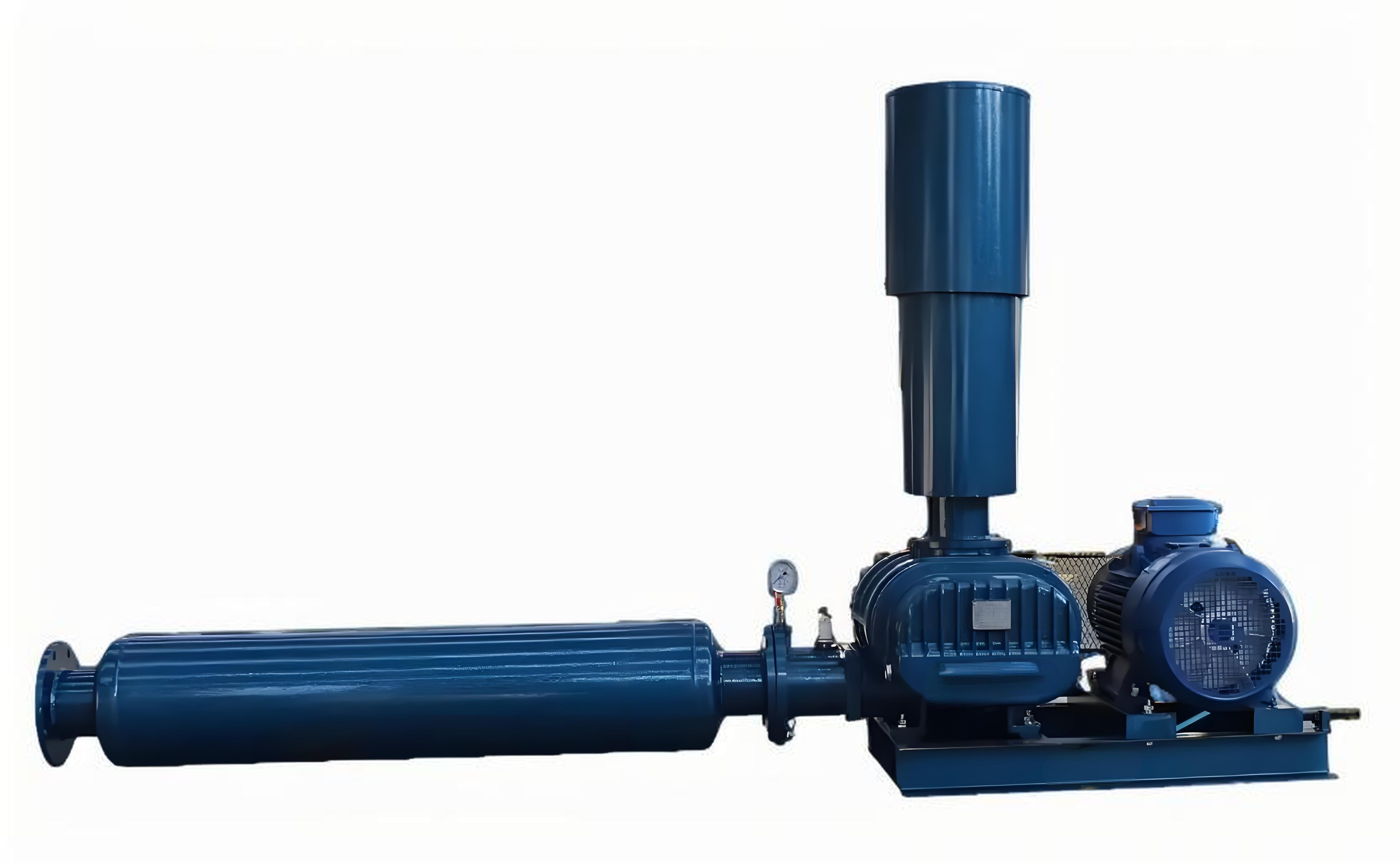

вентилатор от типа roots

Дувач от типа roots представлява важен напредък в технологията за индустриално компресиране на въздуха. Това позитивно дисплейсмънт устройство се състои от два синхронизирани ротора с точно проектирани лопастни части, които завъртат в противоположни посоки в корпуса. Когато тези ротори се въртят, те създават камери, които улавят и преместват въздуха от входа до изхода, произвеждайки постоянен поток на въздух и налягане. Проектът позволява ефикасна работа при различни разлики на налягането, което го прави особено ценен в индустриалните приложения. Тези дувачи работят по прост, но ефективен принцип: въздухът влиза през входния порт, се улавя между роторите и корпуса и след това се изхвърля на по-високо налягане през изхода. Точното машиностроително проектиране на профила на роторите гарантира минимално вътрешно протичане, съхранявайки при това безмаслена операция. Модерните дувачи от типа roots включват продвинати материали и технологии за облагане, за да се подобрят траевността и ефикасността. Те обикновено разполагат с времеви зъбовни колела, които поддържат точна синхронизация на роторите, специални пломби, за да предотвратят забразяването, и прочни подшипници, за да поддържат високоскоростната операция. Многострунността на дувачите от типа roots ги прави незаменими в системи за обработка на стокови води, пневматично транспортиране, индустриални вакуумни системи и различни производствени процеси, където постоянното осигуряване на въздушен поток е важно.