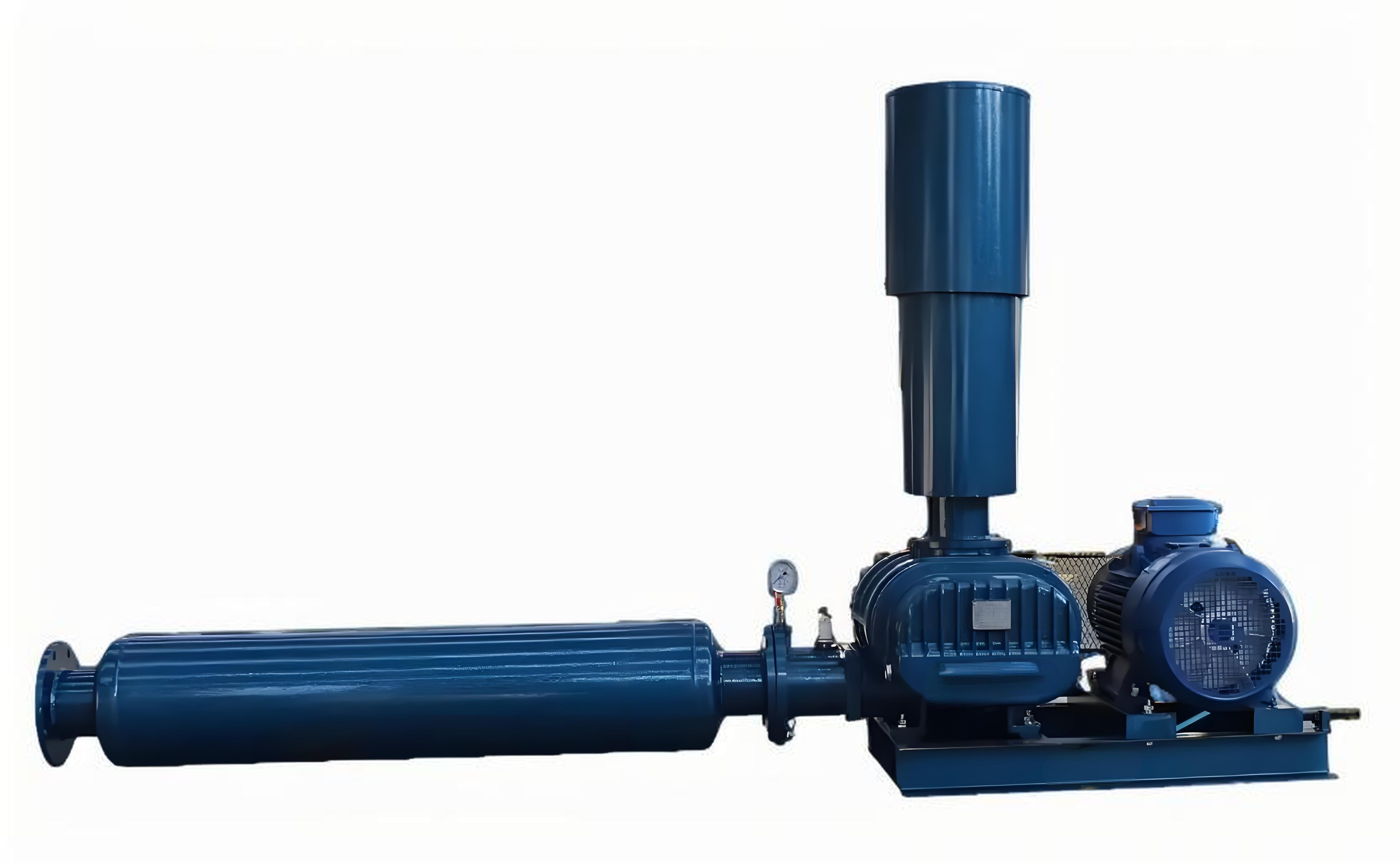

twin lobe blowers

Zwillingslappenblasmaschinen stellen eine grundlegende Technologie in industriellen Luftkompressionsanlagen dar und bieten zuverlässige und effiziente Leistung in verschiedenen Anwendungen. Diese mechanischen Geräte bestehen aus zwei synchronisierten Rotoren mit übereinstimmenden Profilen, die in entgegengesetzter Richtung in einem präzise konstruierten Gehäuse rotieren. Während die Rotoren sich drehen, erzeugen sie Kammern, die Luft am Einlass einfangen, sie durch Rotation komprimieren und sie bei erhöhtem Druck ableiten. Das Design enthält Präzisionszeitantriebsräder, die eine perfekte Synchronisation der Lappen gewährleisten, ohne dass es während des Betriebs zu Metallkontakt kommt. Diese Konfiguration ermöglicht ölfreie Luftkompression, was Zwillingslappenblasmaschinen besonders wertvoll macht in Anwendungen, die einen kontaminationsfreien Luftversorgung benötigen. Das System operiert typischerweise in Geschwindigkeitsbereichen von 500 bis 5000 Umdrehungen pro Minute (RPM) und liefert Druckdifferenziale bis zu 1 Bar in Einzugsstufenkonfigurationen. Moderne Zwillingslappenblasmaschinen integrieren fortschrittliche Funktionen wie Geräuschminderungstechnologien, energieeffiziente Motoren und sophistizierte Steuersysteme für automatisierten Betrieb. Diese Einheiten finden umfangreiche Verwendung in der Abwasserbehandlung, pneumatischen Förderanlagen, industriellen Prozessen und verschiedenen Fertigungsanwendungen, wo eine konsistente Luftversorgung für den Betrieb entscheidend ist.