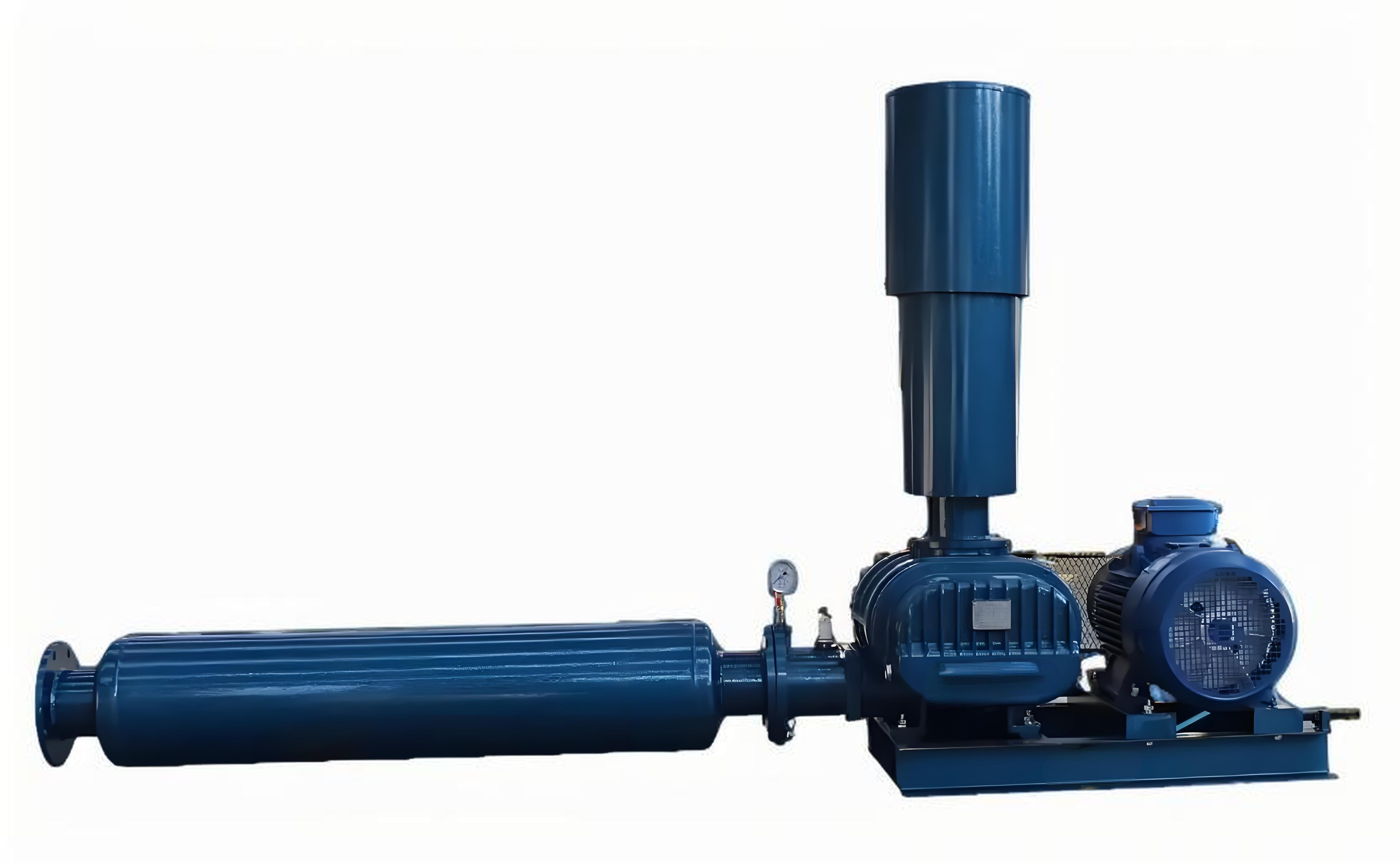

двойни лопастни дувачи

Двуплочните компресори представляват ключова технология в индустриалните системи за компресия на въздуха, предлагайки надежден и ефективен перформанс в различни приложения. Тези механични устройства се състоят от две синхронизирани ротора с идентични профили, които въртят в противоположни посоки в точно изработена кутия. Когато роторите се въртят, те създават камери, които улавят въздуха на входа, го компресират чрез въртене и го изпращат под повишено налягане. Проектирането включва прецизни таймингови греди, които гарантират perfектна синхронизация на плочите без контакт между металите по време на операцията. Тази конфигурация позволява компресия на въздуха без масло, което прави двуплочните компресори особено ценни в приложения, изискващи безконтаминационно осигуряване на въздух. Системата обикновено работи на скорости между 500 и 5000 об. мин., доставяйки разлики в налягането до 1 бар в едностепенни конфигурации. Модерните двуплочни компресори включват продвинати функции като технологии за намаляване на шума, енергийно ефективни мотори и sofisticirani системи за управление за автоматично функциониране. Тези единици намират широка употреба в обработка на комунални стоки, пневматично транспортиране, индустриална обработка и различни производствени приложения, където постоянното осигуряване на въздух е критично за операциите.