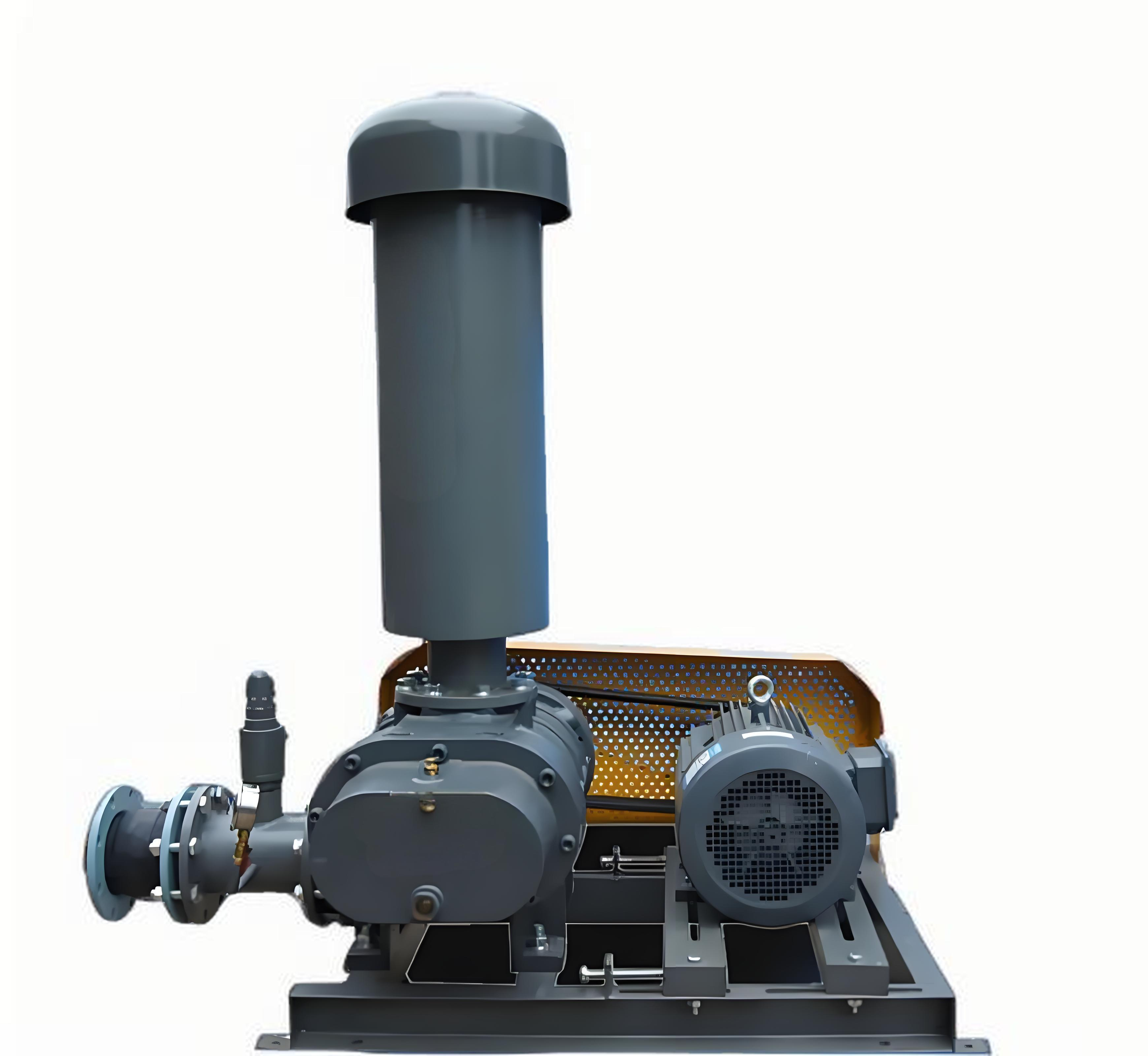

เครื่องเป่าแบบ twin lobe roots

เครื่องเป่าแบบรูทส์สองแคมเป็นนวัตกรรมสำคัญในด้านเทคโนโลยีการบีบอัดอากาศสำหรับอุตสาหกรรม เครื่องจักรชนิดนี้ประกอบด้วยโรเตอร์สองตัวที่ทำงานประสานกัน โดยมีลักษณะโปรไฟล์แบบโลบ์พิเศษซึ่งหมุนไปในทิศทางตรงข้ามภายในโครงสร้างที่ถูกออกแบบมาอย่างละเอียด เมื่อโลบ์ที่ถูกผลิตอย่างแม่นยำเหล่านี้หมุน พวกมันจะสร้างช่องที่สามารถดักจับและเคลื่อนย้ายอากาศหรือก๊าซจากทางเข้าไปยังทางออกได้อย่างมีประสิทธิภาพ เครื่องนี้ทำงานโดยไม่มีการบีบอัดภายใน แต่ใช้หลักการของการแทนที่เพื่อสร้างแรงดัน โดยมีความเร็วรอบระหว่าง 500 ถึง 3600 RPM ทำให้สามารถจัดการปริมาณการไหลตั้งแต่ 100 ถึง 50,000 CFM และสร้างความแตกต่างของแรงดันได้ถึง 15 PSI การก่อสร้างที่แข็งแรงของระบบมักใช้โครงสร้างเหล็กหล่อและโรเตอร์เหล็กกล้าที่ผ่านการ Harden เพื่อให้มั่นใจในความทนทานและการทำงานที่เชื่อถือได้แม้ในสภาพแวดล้อมอุตสาหกรรมที่หนักหน่วง เครื่องเป่าแบบรูทส์สองแคมสมัยใหม่รวมเอาเกียร์จับเวลาขั้นสูง ตลับลูกปืนที่แม่นยำ และระบบซีลเฉพาะที่ทำงานร่วมกันเพื่อรักษาช่องว่างที่เหมาะสมและป้องกันการปนเปื้อน เทคโนโลยีนี้มีการประยุกต์ใช้งานอย่างกว้างขวางในการบำบัดน้ำเสีย การลำเลียงด้วยลม การแยกอากาศ และกระบวนการผลิตต่างๆ ที่จำเป็นต้องมีการไหลของอากาศที่คงที่ ด้วยการออกแบบที่เรียบง่ายแต่มีประสิทธิภาพ ทำให้เหมาะสำหรับการทำงานต่อเนื่องในกระบวนการอุตสาหกรรมที่สำคัญ