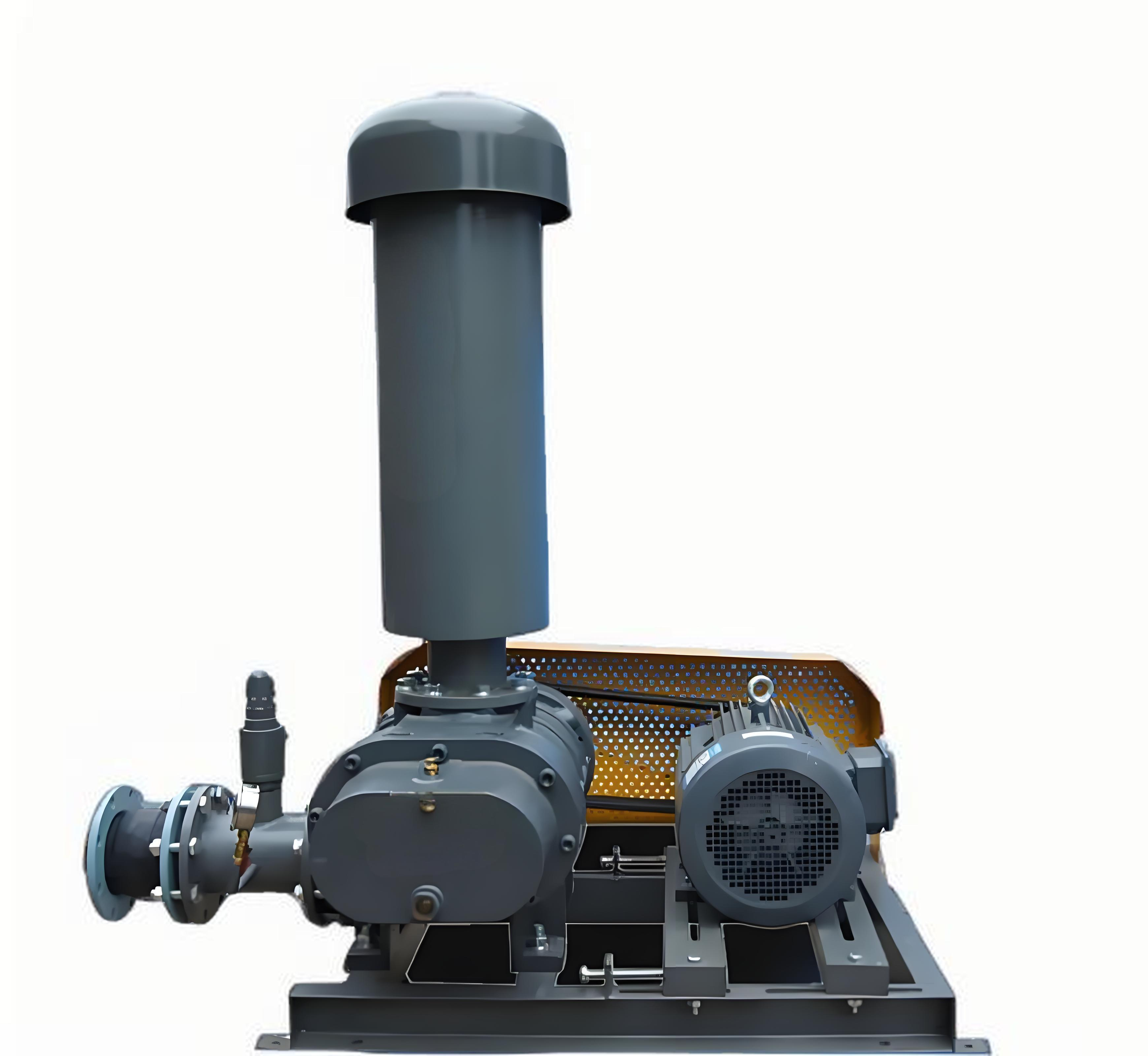

twin lobe roots blower

The twin lobe roots blower represents a pioneering advancement in industrial air compression technology. This mechanical device consists of two synchronized rotors with unique lobe profiles that rotate in opposite directions within a carefully engineered housing. As these precision-crafted lobes rotate, they create chambers that efficiently trap and move air or gas from the inlet to the outlet port. The device operates without internal compression, instead achieving pressure through the displacement principle. Operating at speeds ranging from 500 to 3600 RPM, these blowers can handle flow rates from 100 to 50,000 CFM and generate pressure differentials up to 15 PSI. The system's robust construction typically features cast iron housing and hardened steel rotors, ensuring durability and reliable performance even in demanding industrial environments. Modern twin lobe roots blowers incorporate advanced timing gears, precision bearings, and specialized sealing systems that work together to maintain optimal clearances and prevent contamination. This technology finds extensive application in wastewater treatment, pneumatic conveying, air separation processes, and various manufacturing operations where consistent air flow is crucial. The design's simplicity, combined with its effectiveness, makes it an ideal choice for continuous operation in critical industrial processes.