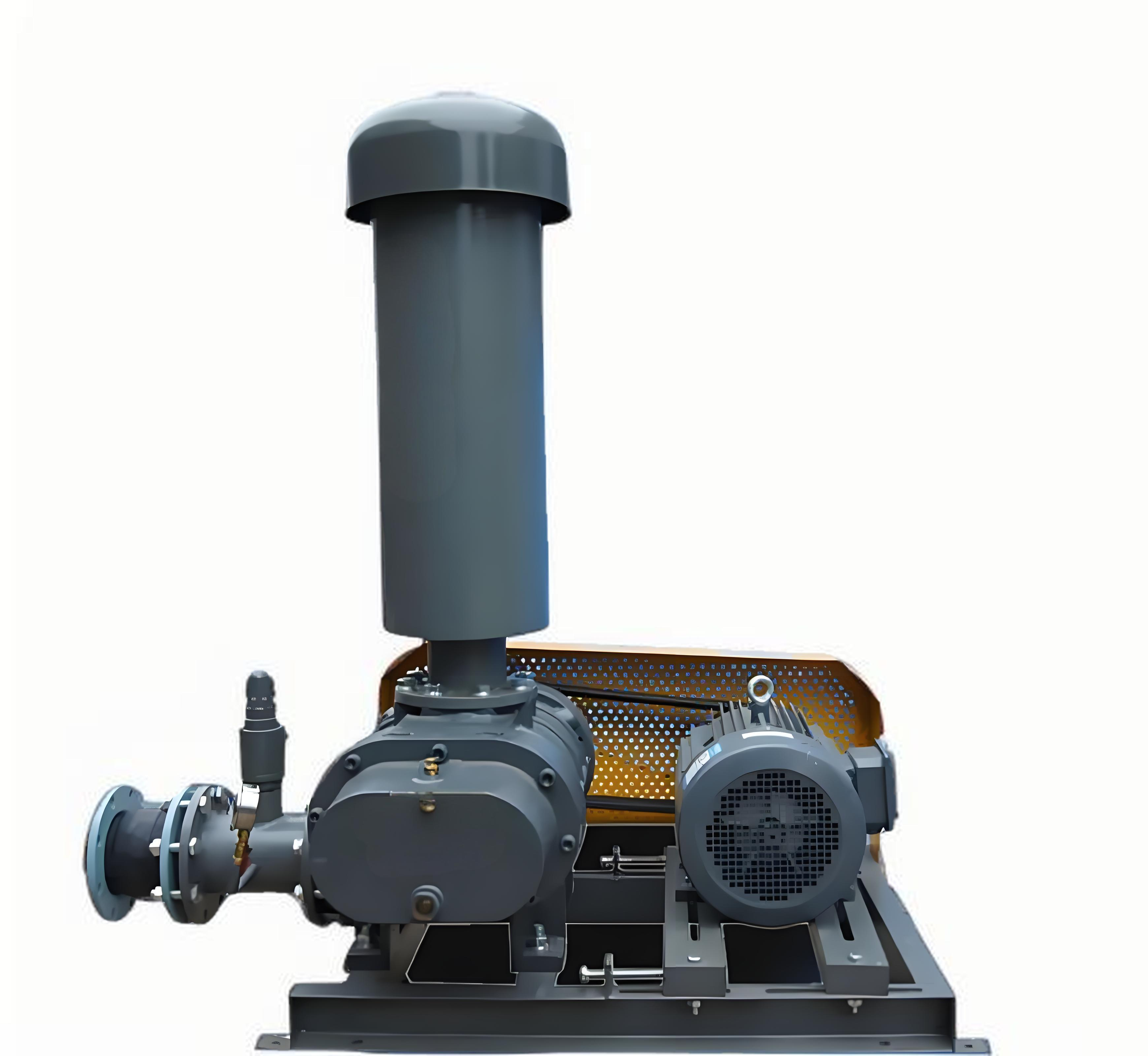

air blower for aeration tank

Air blowers for aeration tanks represent essential equipment in wastewater treatment systems, delivering vital oxygen to support biological processes. These specialized devices are engineered to provide continuous, reliable airflow that maintains optimal dissolved oxygen levels in aeration tanks. The system typically consists of a motor-driven impeller that generates high-volume air movement, paired with advanced control mechanisms for precise output regulation. Modern air blowers incorporate energy-efficient designs, featuring variable frequency drives that adjust output based on demand, significantly reducing operational costs. These units are constructed with durability in mind, utilizing corrosion-resistant materials to withstand the challenging environments of water treatment facilities. The blowers can be configured for various tank sizes and shapes, with options for both surface-mounted and submersible installations. They integrate seamlessly with existing treatment infrastructure and often include monitoring systems that provide real-time performance data. The technology behind these blowers continues to evolve, with newer models offering improved efficiency ratios and reduced noise levels compared to traditional designs. This equipment plays a crucial role in maintaining water quality standards and ensuring the effectiveness of the entire treatment process.