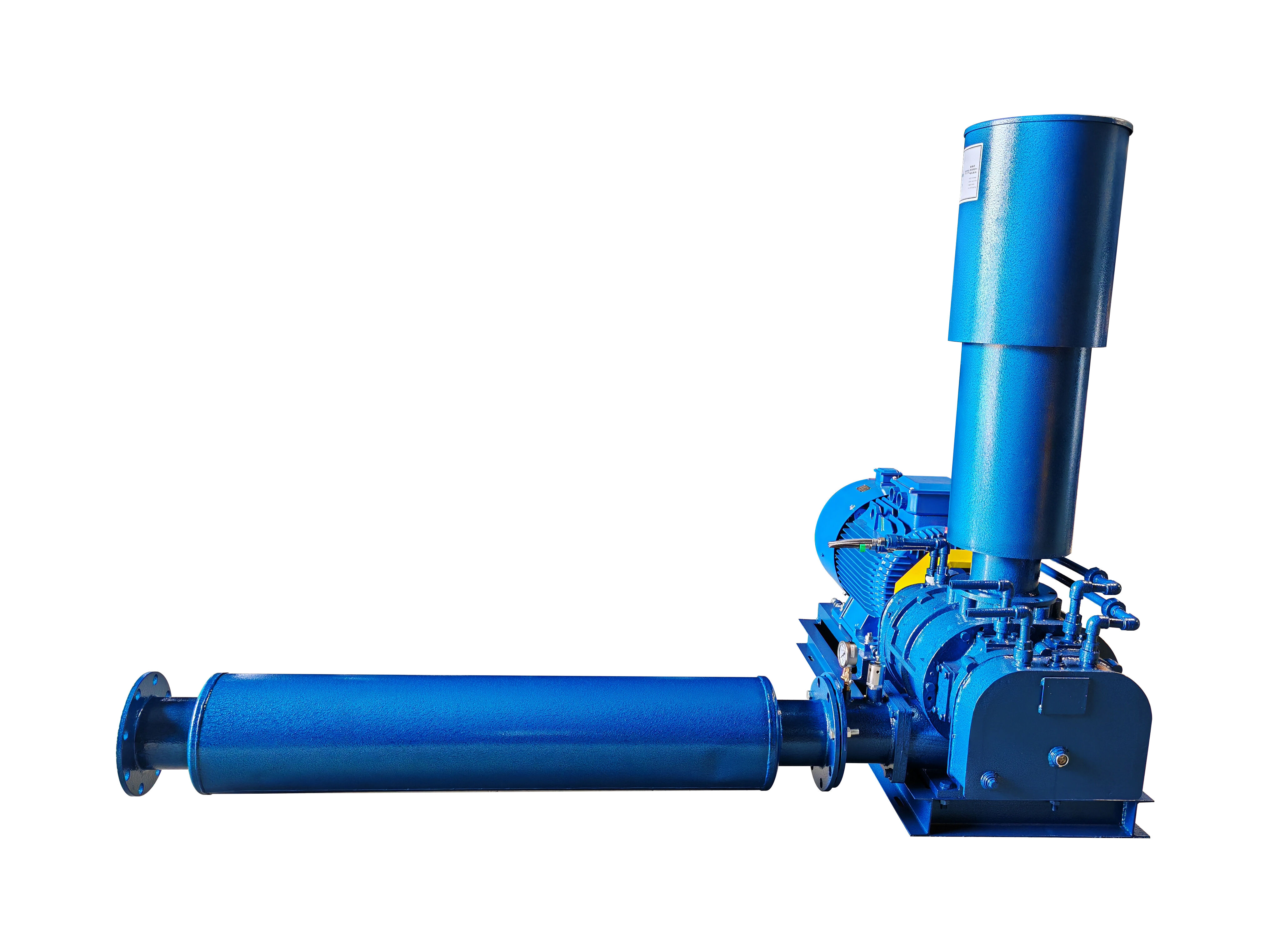

centrifugal blower fan price

Centrifugal blower fan pricing represents a crucial consideration in industrial and commercial ventilation systems. These essential components, known for their reliability and efficiency, operate by drawing air into a rotating impeller that accelerates and discharges it radially. The price range varies significantly based on factors such as size, material quality, motor specifications, and advanced features. Modern centrifugal blower fans incorporate cutting-edge technology, including variable frequency drives, energy-efficient motors, and precision-engineered impellers. They find widespread applications across diverse industries, from HVAC systems and industrial processes to material handling and dust collection. The pricing structure typically reflects the fan's capacity, measured in cubic feet per minute (CFM), pressure capabilities, and overall build quality. Manufacturers often offer customization options, impacting the final price point. When evaluating centrifugal blower fan prices, buyers must consider long-term operational costs, including energy consumption, maintenance requirements, and expected service life. The investment in a quality centrifugal blower fan often translates to improved system efficiency and reduced operational expenses over time.