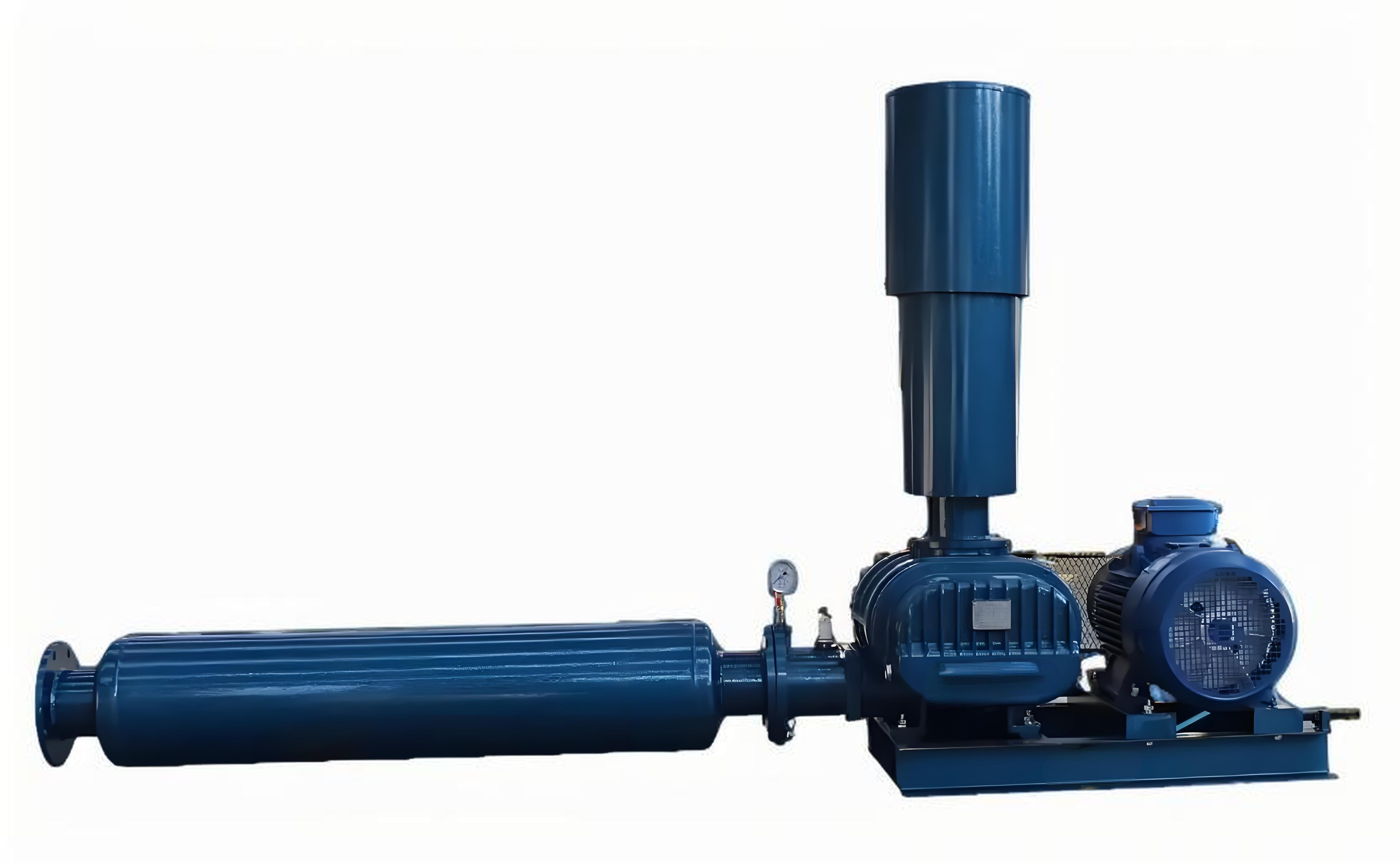

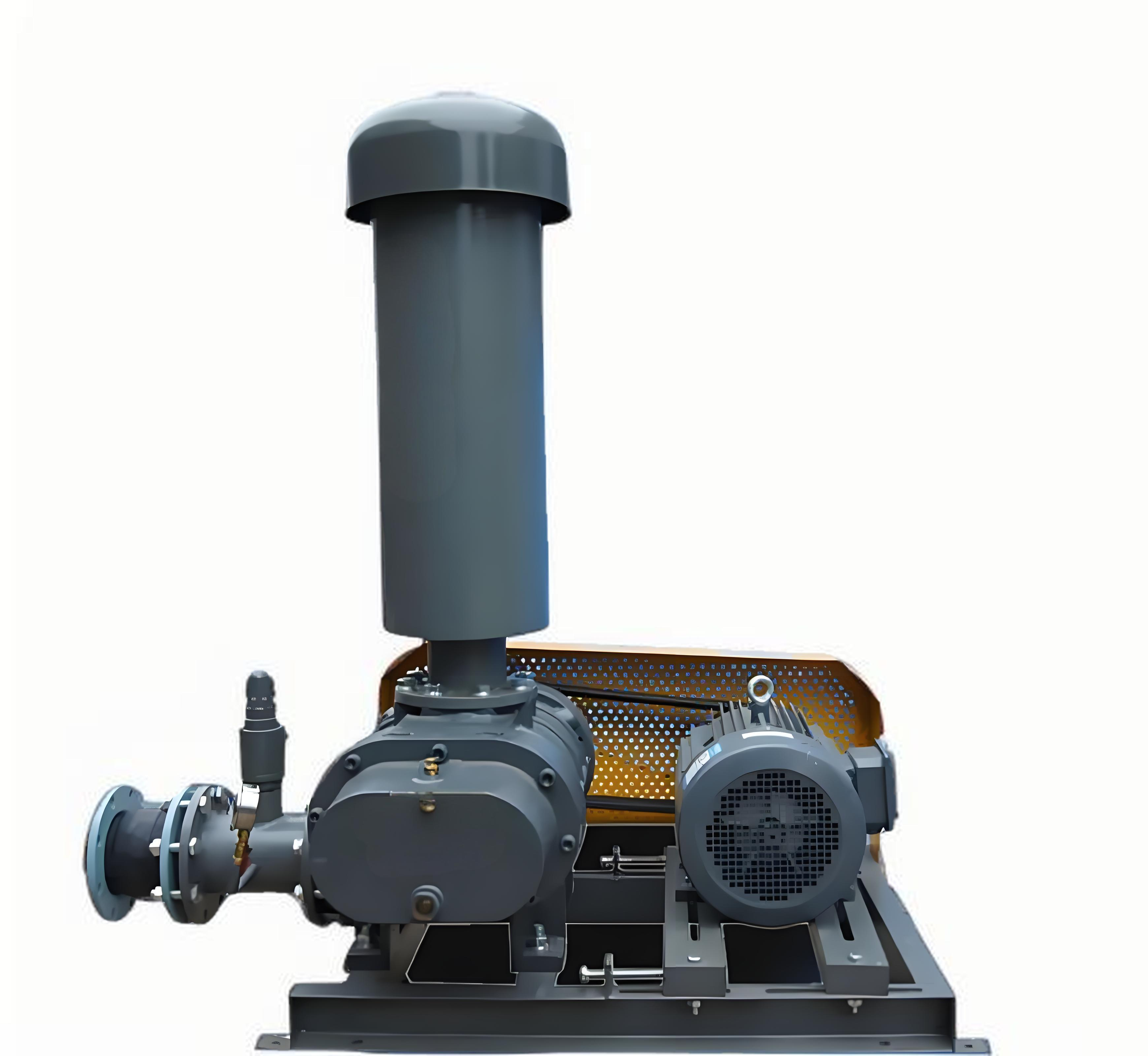

high pressure centrifugal fan

High pressure centrifugal fans represent a crucial component in industrial ventilation and air handling systems, engineered to deliver powerful airflow against significant system resistance. These robust machines operate by converting mechanical energy into kinetic energy through the rapid rotation of specially designed impeller blades. As air enters the fan housing through the central inlet, it encounters the spinning impeller, which accelerates the air outward using centrifugal force. This process creates a substantial pressure differential that enables the fan to move large volumes of air efficiently. The high pressure capability makes these fans particularly valuable in applications requiring forceful air movement through complex ductwork, filtration systems, or against process resistance. Modern high pressure centrifugal fans incorporate advanced features such as precision-balanced impellers, heavy-duty bearings, and aerodynamically optimized housing designs. These elements work together to ensure reliable performance while maintaining energy efficiency. The fans are available in various configurations, including single and double inlet designs, backward or forward curved blades, and different mounting arrangements to suit specific installation requirements. They play vital roles in industries ranging from cement manufacturing and power generation to chemical processing and waste treatment facilities, where their ability to maintain consistent airflow under demanding conditions is essential for process efficiency and system reliability.