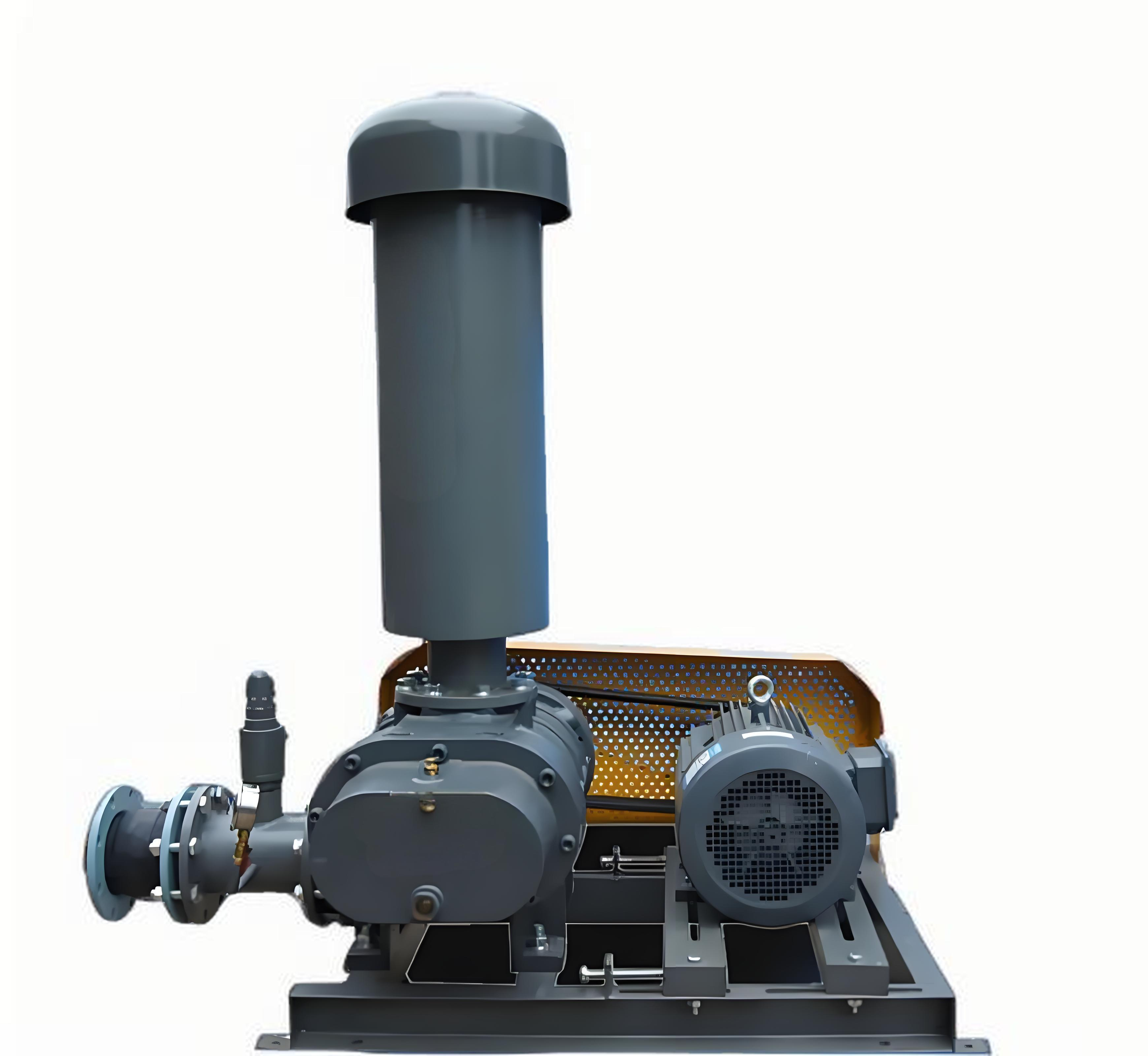

low price directly connected roots blower

The low price directly connected roots blower represents a significant advancement in industrial air movement technology, offering an efficient and cost effective solution for various applications. This innovative system features a direct drive mechanism that eliminates the need for belt drives or complex transmission systems, resulting in reduced maintenance requirements and improved operational reliability. The blower utilizes two precision engineered rotors that rotate in opposite directions, creating a continuous flow of air or gas. With its robust construction and streamlined design, this roots blower delivers consistent performance while maintaining optimal energy efficiency. The system operates at various pressure differentials and can handle flow rates suitable for numerous industrial processes. The direct connection between the motor and blower significantly reduces mechanical losses, leading to better overall system efficiency. These units are particularly valuable in applications requiring continuous operation, such as wastewater treatment, pneumatic conveying, and industrial process automation. The sophisticated engineering behind these blowers ensures minimal vibration and noise levels, making them suitable for indoor installation and operation in various industrial environments.