mechanical steam compression

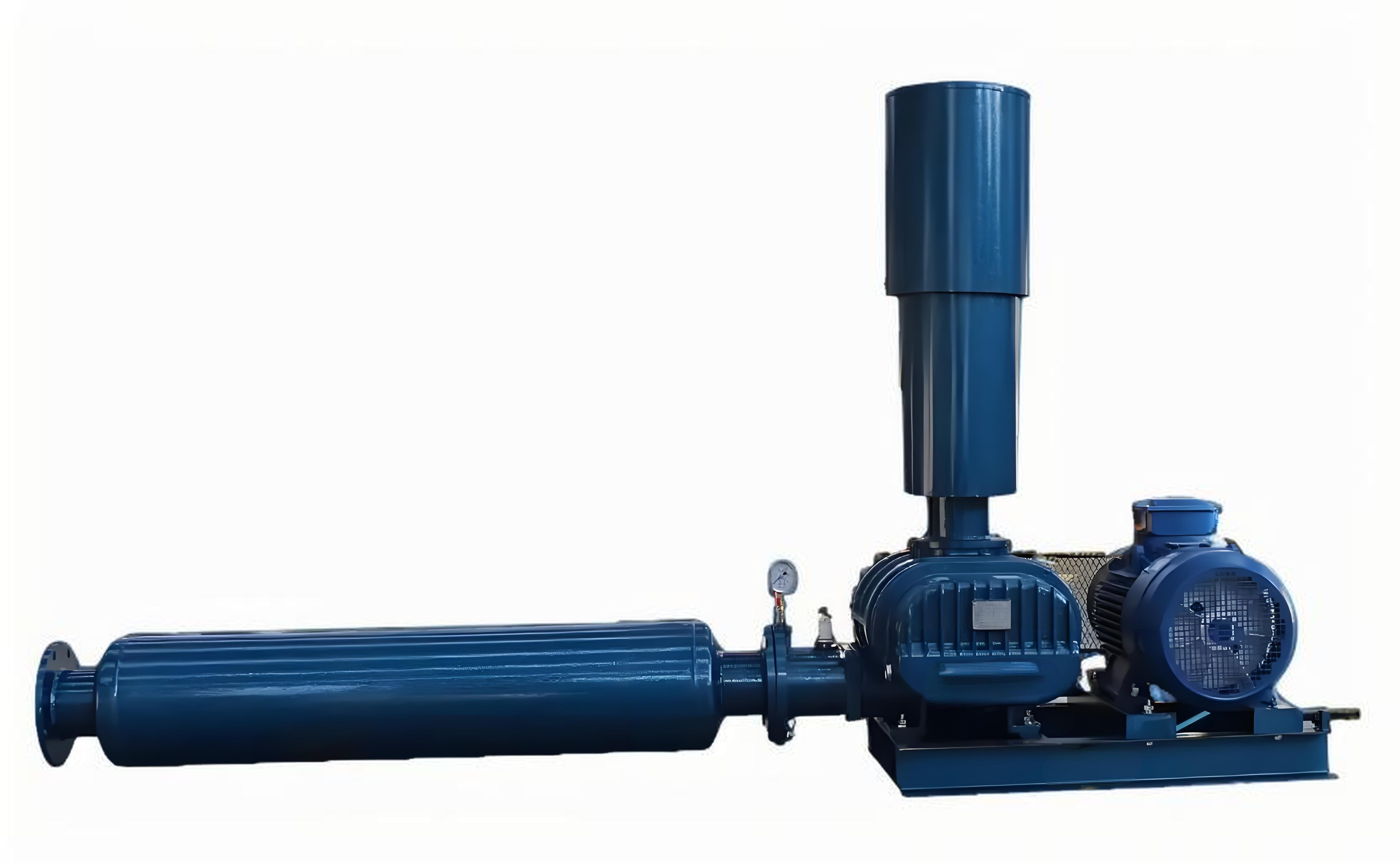

Mechanical steam compression is an advanced industrial process that efficiently reuses steam energy by compressing low-pressure steam to generate high-pressure steam. This technology operates through a mechanical compressor that increases the pressure and temperature of waste steam, making it suitable for reuse in various industrial applications. The system consists of several key components, including a compressor unit, drive motor, control system, and heat exchangers. The process begins when low-pressure steam enters the compression chamber, where it undergoes mechanical compression, resulting in increased pressure and temperature. This compressed steam can then be utilized for various industrial processes, such as heating, drying, or power generation. The technology is particularly valuable in industries where steam is a crucial component of manufacturing processes, including food processing, chemical production, and paper manufacturing. Modern mechanical steam compression systems are equipped with sophisticated control systems that optimize performance and energy efficiency, while maintaining precise temperature and pressure control. The technology has evolved to include features such as variable speed drives, advanced monitoring systems, and automated operation capabilities, making it a versatile solution for industrial steam management.