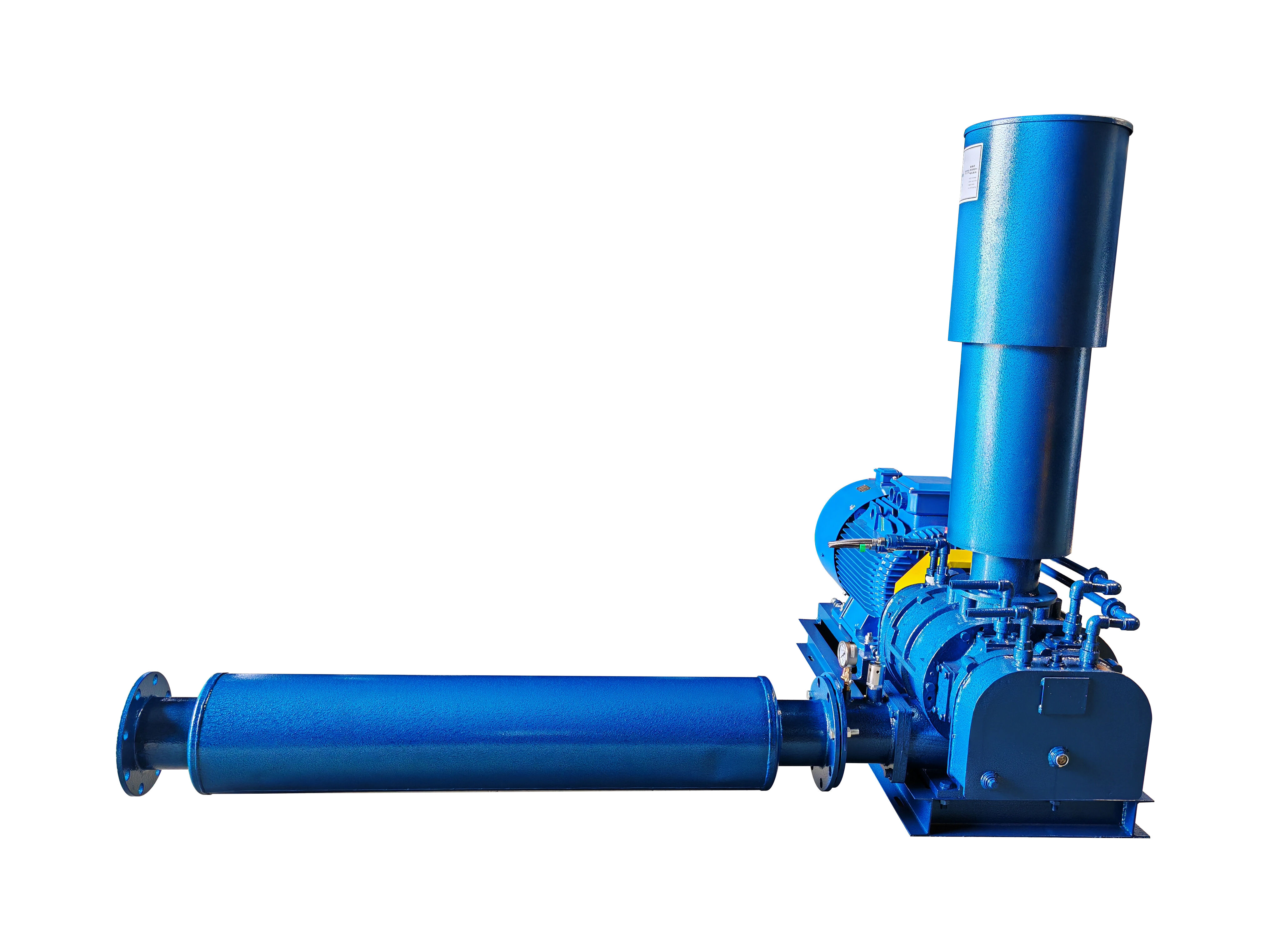

vapour recovery compressor

A vapor recovery compressor is a specialized industrial equipment designed to capture, compress, and recover volatile organic compounds (VOCs) and other vapor emissions that would otherwise escape into the atmosphere. This advanced system plays a crucial role in environmental protection and resource conservation across various industries. The compressor operates by drawing in vapor-phase chemicals through a sophisticated intake system, then compressing these gases to convert them back into their liquid state for reuse or proper disposal. The technology incorporates multiple stages of compression, utilizing either rotary screw, reciprocating, or liquid ring designs, depending on the specific application requirements. These systems are equipped with advanced monitoring and control mechanisms that ensure optimal performance while maintaining safety standards. Vapor recovery compressors find extensive applications in petrochemical facilities, storage terminals, loading stations, and various manufacturing processes where volatile compounds are present. They are particularly vital in operations involving fuel storage, transfer, and distribution, where they help prevent product loss and ensure compliance with environmental regulations. The system's design typically includes features such as explosion-proof components, automated pressure control, and efficient cooling mechanisms to handle various types of vapor streams effectively.