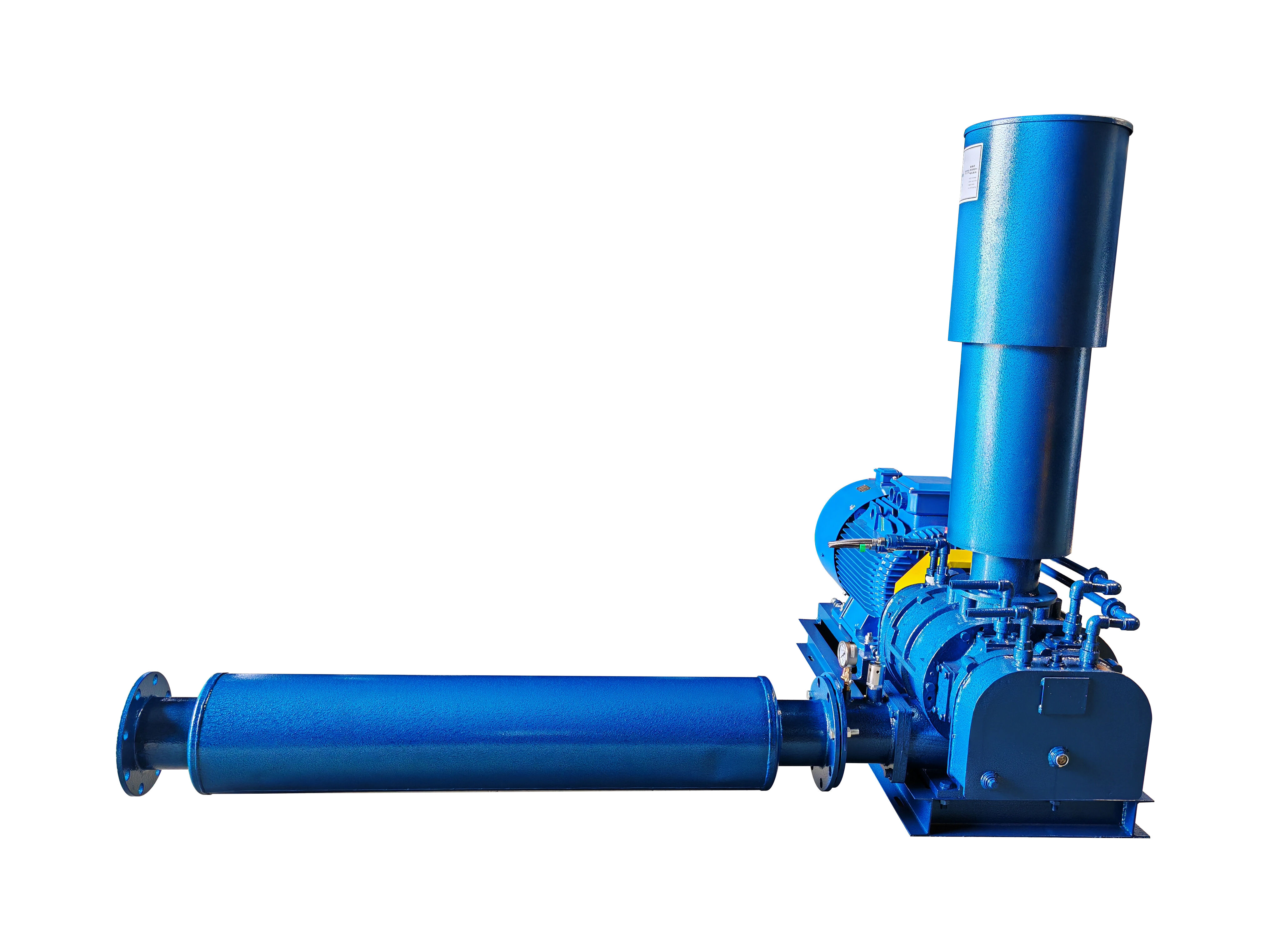

small centrifugal blower

A small centrifugal blower represents a compact yet powerful air-moving device that operates on the principle of centrifugal force to generate airflow. This innovative device features a rotating impeller that draws air in axially and discharges it radially, creating a steady, high-pressure airstream. The design incorporates precision-engineered components, including curved blades mounted on a wheel or rotor, which spins at high speeds to effectively move air or gases. The blower's compact size makes it ideal for installations where space is at a premium, while its efficient motor design ensures optimal performance with minimal energy consumption. These blowers typically operate with direct drive systems, eliminating the need for belt maintenance and reducing operational costs. The construction often features durable materials such as reinforced thermoplastic or aluminum, providing excellent corrosion resistance and long-term reliability. Modern small centrifugal blowers often come equipped with variable speed controls, allowing users to adjust airflow according to specific requirements. Their applications span across various industries, from HVAC systems and electronic cooling to industrial process ventilation and medical equipment.