three blade roots blower vendors

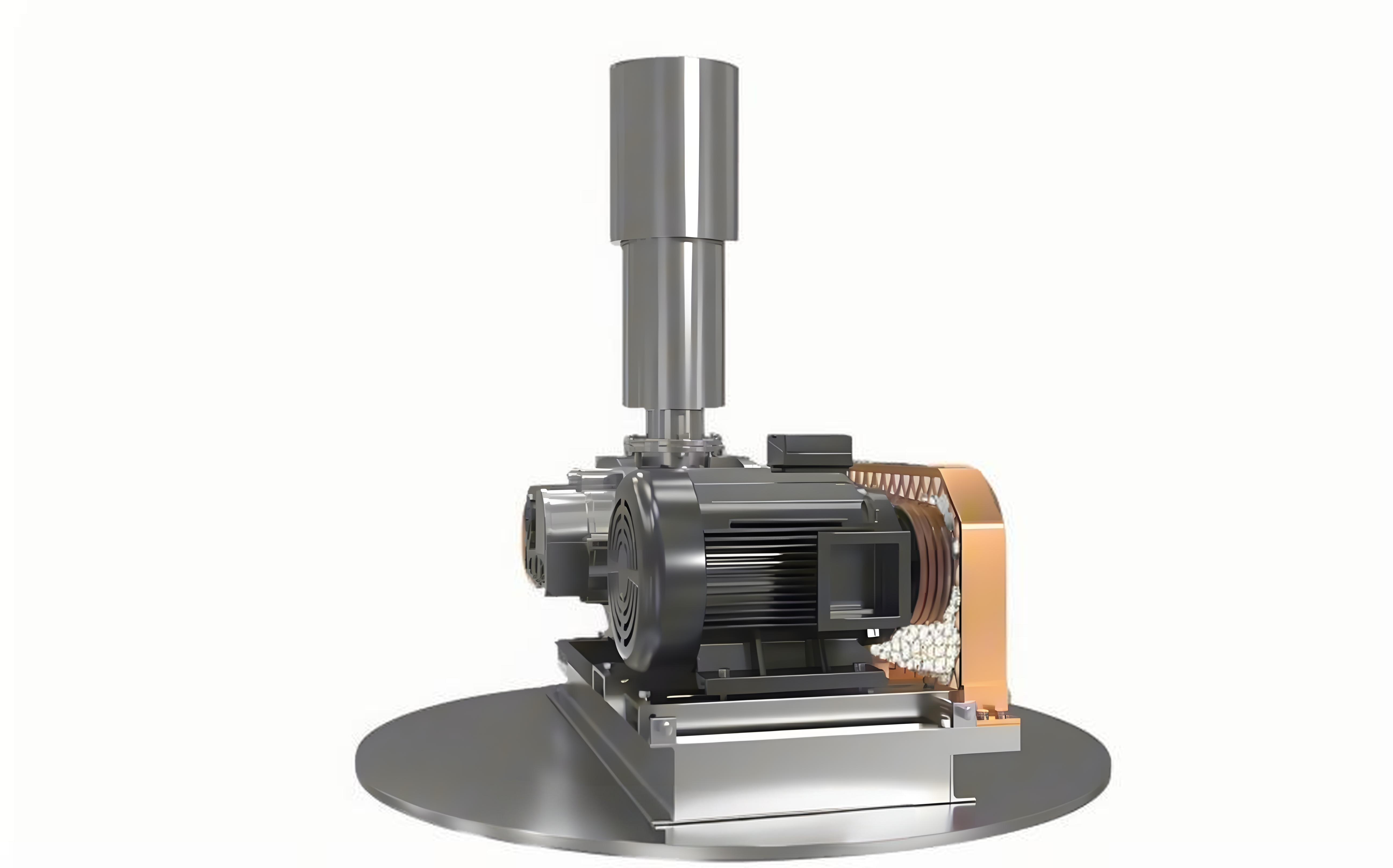

Three blade roots blower vendors represent the cutting edge in industrial air movement technology, offering robust solutions for various applications. These manufacturers specialize in producing high-performance blowers that utilize a triple-lobe design, marking a significant advancement over traditional two-blade systems. The core technology incorporates precision-engineered rotors that maintain tight clearances while operating, ensuring optimal efficiency and reduced energy consumption. These vendors focus on delivering products that excel in both continuous and intermittent operations, with designs specifically engineered to handle pressure differentials ranging from 0.5 to 1 bar. The blowers feature advanced coating technologies that enhance durability and resist wear, particularly in demanding industrial environments. A key technological feature is the implementation of synchronized gear systems that maintain perfect timing between the three rotating elements, resulting in smoother operation and reduced vibration levels. These vendors also incorporate modern manufacturing techniques, including computer-aided design and precision machining, to ensure consistent quality across their product lines. Applications span various industries, including wastewater treatment, pneumatic conveying, food processing, and chemical manufacturing, where reliable air movement is crucial for operations.