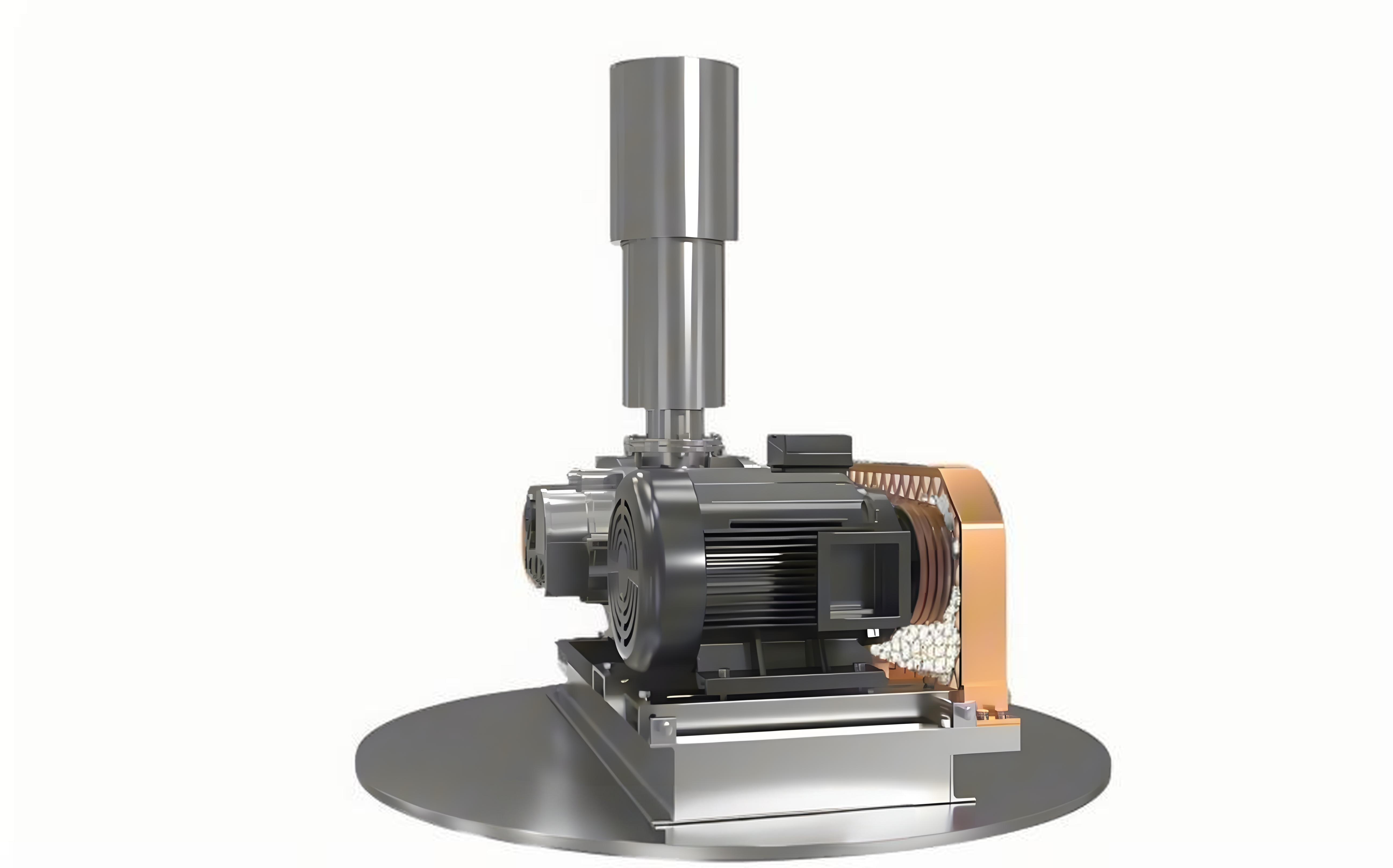

двойен лопастен въздушен дувач

Двуетажният вентилатор за въздух представлява съществено подобряване в технологията за индустриално компресиране на въздух, работейки чрез точно инженерна система от два синхронизирани ротора. Тези ротори, работещи в перфектна хармония, създават непрекъснат поток въздух, като затварят и компресират въздуха между лопастите и корпуса на вентилатора. Устройството работи по принципа на позитивно разместване, доставяйки постоянен обем въздух независимо от промените в налягането. Системата се състои от два ротора с формата на осем, които завиват в противоположни посоки вътре в точно инженерен корпус, запазвайки тясни разстояния без реален контакт. Този дизайн гарантира ефикасно компресиране на въздуха, минимизирайки износът и нуждите за поддръжка. Модерните двуетажни вентилатори включват напреднали материали и прецизни технологии за производство, което води до подобрена ефективност и намалени нива на шума. Те се ценят особено за способността си да доставят маслосвободен въздух, правейки ги идеални за приложения, където чистотата на въздуха е от ключово значение. Робустното си строителство и надеждните характеристики на производителността правят двуетажните вентилатори основни в различни индустриални процеси, от обработка на стоки до пневматични системи за транспортиране. Технологията е развълнувана, за да включва sofisticirani времеви греди, специализирани системи за затваряне и оптимизирани профили на лопастите, които колективно подобряват производителността и операционната надеждност.