Understanding the Impact of Blower Systems on Aeration Performance

The relationship between blower design and aeration efficiency stands as a critical factor in wastewater treatment, industrial processes, and aquaculture systems. Modern blower technologies have evolved significantly, offering unprecedented levels of efficiency and control in aeration applications. As industries strive for more sustainable and cost-effective operations, the importance of optimizing blower design for maximum aeration efficiency has never been more paramount.

The intricate connection between blower design and aeration efficiency encompasses multiple factors, from impeller geometry to control systems. Each component plays a vital role in determining how effectively air is delivered to the process, ultimately affecting both operational costs and treatment outcomes. Understanding these relationships helps operators and engineers make informed decisions about system design and optimization.

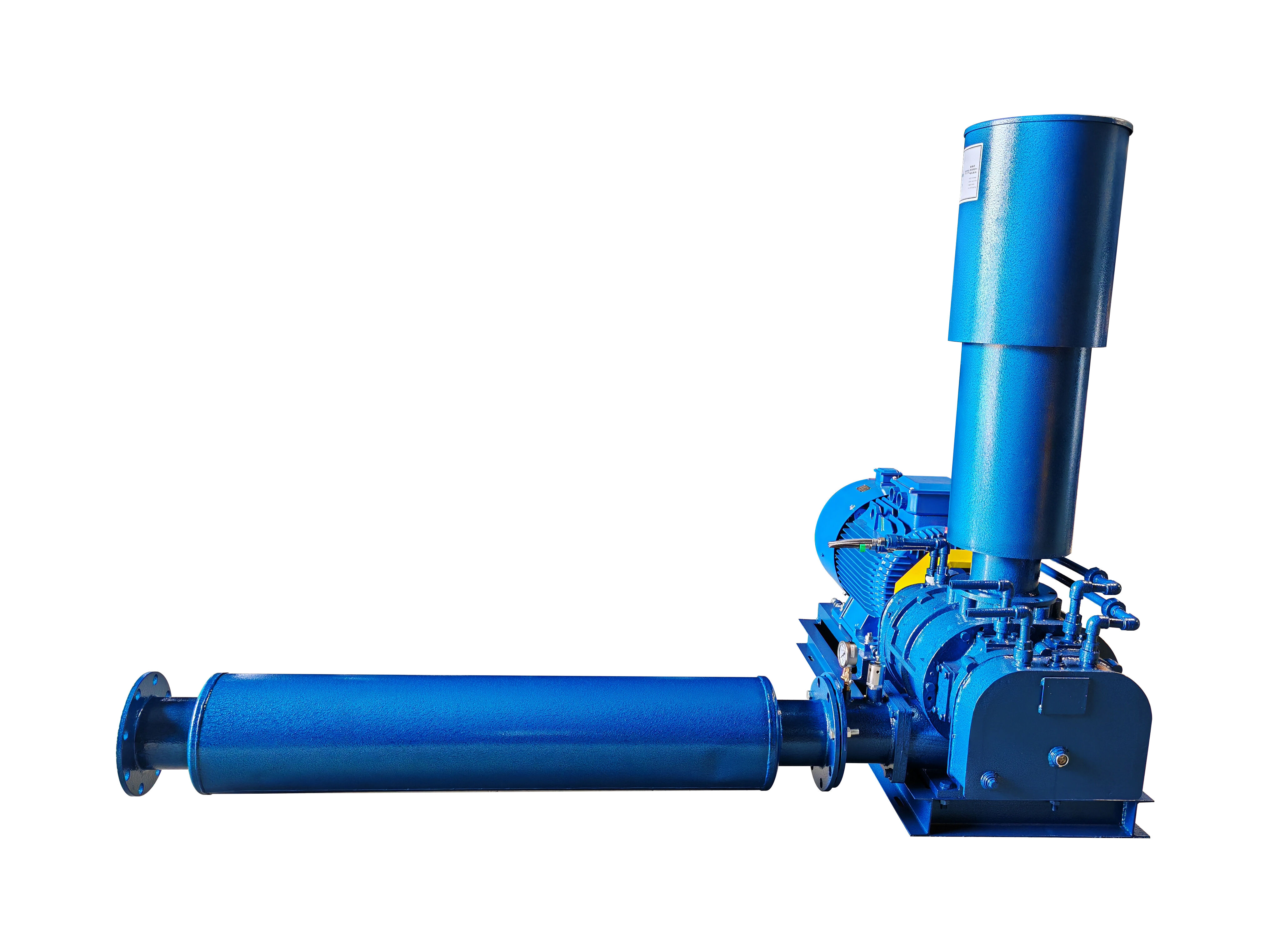

Core Components of Modern Blower Systems

Impeller Design and Performance

The impeller serves as the heart of any blower system, and its design directly influences blower design aeration efficiency. Advanced impeller configurations feature precisely engineered blade profiles that maximize air movement while minimizing energy consumption. Modern designs often incorporate backward-curved blades that reduce turbulence and optimize airflow patterns.

Material selection for impellers has also evolved, with manufacturers now utilizing high-strength alloys and composite materials that offer superior durability and aerodynamic properties. These innovations enable sustained high performance while reducing maintenance requirements and extending equipment lifespan.

Housing and Airflow Path Configuration

The blower housing design plays a crucial role in directing airflow and maintaining optimal operating conditions. Modern housings feature streamlined flow paths that minimize resistance and turbulence, contributing significantly to overall blower design aeration efficiency. Computational fluid dynamics analysis helps engineers optimize these pathways for maximum performance.

Advanced sealing systems and thermal management features within the housing design help maintain consistent operating temperatures and prevent air leakage. These elements ensure that the blower operates at peak efficiency throughout its service life, reducing energy waste and maintaining reliable performance.

Technology Innovations in Blower Control Systems

Smart Control Integration

Modern blower systems incorporate sophisticated control technologies that continuously monitor and adjust operating parameters. These smart systems optimize blower design aeration efficiency by matching output to actual demand, preventing energy waste from over-aeration. Real-time monitoring capabilities allow operators to track performance metrics and make informed decisions about system operation.

Integration with plant-wide control systems enables coordinated operation of multiple blowers, ensuring optimal distribution of air throughout the process. Advanced algorithms can predict maintenance needs and adjust operation patterns to maximize efficiency while minimizing wear on system components.

Variable Frequency Drive Applications

Variable frequency drives (VFDs) represent a significant advancement in blower control technology. By allowing precise speed control, VFDs enable blowers to maintain optimal blower design aeration efficiency across varying load conditions. This flexibility results in substantial energy savings compared to traditional fixed-speed systems.

Modern VFD systems also incorporate advanced features such as soft start capabilities and harmonic distortion reduction, which protect equipment and extend service life while maintaining efficient operation. The ability to fine-tune blower speed in response to changing conditions ensures consistent treatment quality while minimizing energy consumption.

Efficiency Optimization Strategies

System Sizing and Selection

Proper sizing of blower systems is crucial for achieving optimal blower design aeration efficiency. Oversized systems waste energy and increase operational costs, while undersized systems may fail to meet process requirements. Engineers must carefully consider factors such as peak demand, turndown requirements, and system head loss when selecting appropriate blower configurations.

Modern design tools and simulation software help engineers evaluate different scenarios and select the most efficient solution for specific applications. This approach ensures that installed systems provide the necessary performance while minimizing energy consumption and operating costs.

Maintenance and Performance Monitoring

Regular maintenance and performance monitoring play vital roles in maintaining blower design aeration efficiency over time. Scheduled inspections, cleaning, and component replacement help prevent efficiency losses due to wear or contamination. Advanced monitoring systems provide early warning of potential issues, allowing operators to address problems before they impact performance.

Data analysis tools help identify trends and opportunities for improvement, enabling operators to optimize system settings and maintenance schedules. This proactive approach helps maintain peak efficiency while extending equipment life and reducing operational costs.

Environmental and Economic Benefits

Energy Conservation Impact

Efficient blower design directly contributes to reduced energy consumption, resulting in significant cost savings and environmental benefits. Modern systems can achieve energy reductions of 30-50% compared to older technologies, representing substantial operational cost savings for facilities.

The environmental impact of improved blower design aeration efficiency extends beyond energy savings, including reduced carbon emissions and smaller overall environmental footprint. These benefits align with increasingly stringent environmental regulations and sustainability goals.

Long-term Cost Analysis

While advanced blower systems may require higher initial investment, the long-term economic benefits often justify the cost. Improved efficiency, reduced maintenance requirements, and longer equipment life contribute to favorable return on investment calculations. Organizations must consider total lifecycle costs when evaluating blower system options.

The financial impact of efficient blower design extends beyond direct energy savings to include reduced maintenance costs, improved process stability, and potential regulatory compliance benefits. These factors contribute to the overall value proposition of investing in high-efficiency blower systems.

Frequently Asked Questions

What is the optimal operating range for maximum blower efficiency?

Most modern blowers achieve peak efficiency when operating between 60-80% of their maximum capacity. This range provides the best balance between energy consumption and performance, while maintaining adequate turndown capability for varying demand conditions.

How often should blower system performance be evaluated?

Regular performance evaluations should be conducted quarterly, with continuous monitoring through automated systems. This schedule allows for timely identification of efficiency losses and optimization opportunities while maintaining optimal system performance.

What factors most significantly impact blower efficiency over time?

The primary factors affecting long-term blower efficiency include mechanical wear, impeller fouling, seal degradation, and control system calibration drift. Regular maintenance and monitoring help address these factors and maintain optimal performance levels.