Selecting the appropriate oxidation blower supplier is a critical decision that directly impacts your industrial operations' efficiency, reliability, and long-term success. The oxidation process in various industries requires specialized equipment that can deliver consistent airflow, maintain optimal pressure levels, and operate reliably under demanding conditions. Whether you're managing wastewater treatment facilities, chemical processing plants, or manufacturing operations, the right supplier partnership ensures your oxidation systems perform at peak efficiency while minimizing operational disruptions and maintenance costs.

Understanding Oxidation Blower Technology and Applications

Core Technology Behind Modern Oxidation Systems

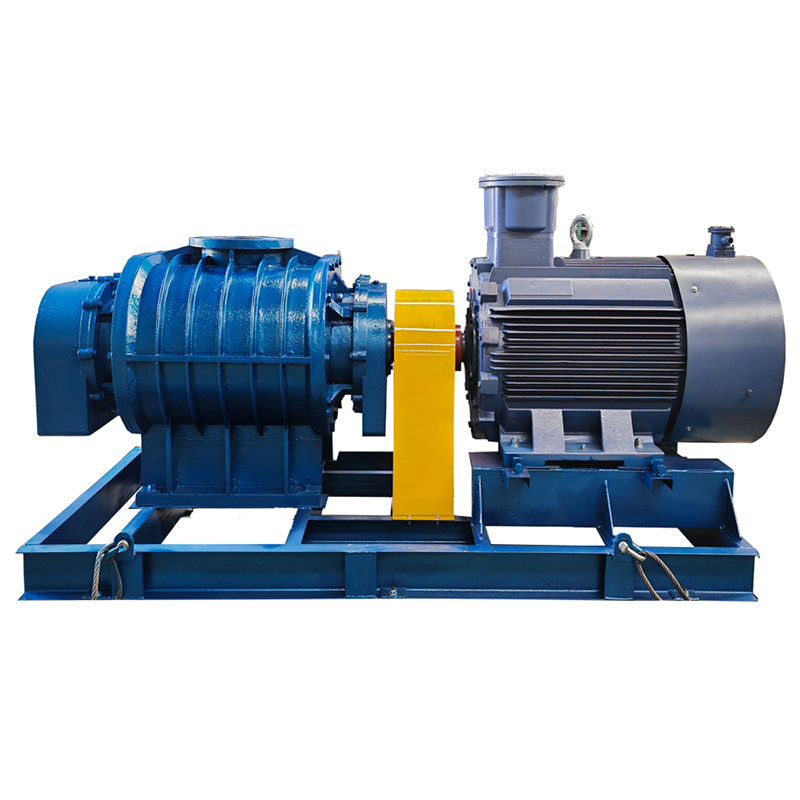

Modern oxidation blower technology encompasses various designs including positive displacement blowers, centrifugal blowers, and turbo blowers, each engineered to meet specific industrial requirements. Positive displacement blowers provide consistent airflow regardless of system pressure changes, making them ideal for applications requiring steady oxygen delivery. These systems utilize rotating lobes or screws to move air through sealed chambers, ensuring precise volume control and minimal efficiency losses even under varying load conditions.

The selection between different blower technologies depends heavily on your specific oxidation requirements, including required flow rates, pressure specifications, and energy efficiency targets. Centrifugal blowers excel in high-volume applications where variable flow control is essential, while turbo blowers offer superior energy efficiency for large-scale operations. Understanding these technological differences enables informed supplier selection based on your facility's unique operational parameters and performance expectations.

Industrial Applications and Performance Requirements

Oxidation blowers serve critical functions across diverse industrial sectors, from municipal wastewater treatment plants requiring continuous aeration for biological processes to chemical manufacturing facilities needing precise oxidation control for product quality. In wastewater treatment applications, oxidation blowers must deliver consistent oxygen levels to support microbial communities responsible for breaking down organic pollutants, requiring reliable operation with minimal maintenance interruptions.

Chemical processing industries demand oxidation blowers capable of handling corrosive environments while maintaining precise flow control for reaction optimization. Food and beverage processing facilities utilize oxidation systems for various applications including fermentation control and product preservation, requiring equipment that meets strict hygiene standards while delivering consistent performance. Understanding your industry's specific requirements helps identify suppliers with relevant experience and appropriate equipment certifications.

Key Supplier Evaluation Criteria

Technical Expertise and Engineering Capabilities

Evaluating a supplier's technical expertise involves examining their engineering team's qualifications, project experience, and ability to provide customized solutions for your specific oxidation requirements. Leading suppliers employ experienced engineers who understand the complexities of oxidation processes and can recommend optimal blower configurations based on your facility's unique parameters. This expertise includes knowledge of airflow dynamics, pressure optimization, and system integration considerations that directly impact operational efficiency.

Comprehensive technical support extends beyond initial equipment selection to include system design assistance, installation guidance, and ongoing optimization recommendations. Quality suppliers provide detailed technical documentation, performance curves, and modeling services that help predict system behavior under various operating conditions. This level of technical support ensures your oxidation blower installation achieves optimal performance from startup through long-term operation.

Quality Standards and Manufacturing Processes

Manufacturing quality directly impacts equipment reliability, operational lifespan, and maintenance requirements throughout your oxidation blower's service life. Reputable suppliers maintain rigorous quality control processes including material certification, precision machining standards, and comprehensive testing protocols that verify equipment performance before shipment. These quality measures ensure consistent product reliability and minimize the risk of premature failures that could disrupt critical oxidation processes.

Industry certifications such as ISO 9001 quality management systems, API standards compliance, and environmental certifications demonstrate a supplier's commitment to maintaining consistent quality standards. Additionally, suppliers utilizing advanced manufacturing technologies including CNC machining, automated assembly processes, and computerized quality control systems typically deliver superior product consistency and reliability compared to those using conventional manufacturing methods.

Service and Support Considerations

Installation and Commissioning Support

Professional installation and commissioning services are essential for ensuring optimal oxidation blower performance from initial startup through long-term operation. Experienced suppliers provide comprehensive installation support including site preparation guidance, equipment positioning recommendations, and system integration assistance that minimizes installation complications and reduces startup timeframes. This support is particularly valuable for complex installations requiring precise alignment, specialized mounting, or integration with existing control systems.

Commissioning services should include performance verification testing, system calibration, and operator training programs that ensure your personnel can effectively operate and maintain the oxidation equipment. Quality suppliers provide detailed commissioning documentation including performance test results, operational parameters, and maintenance schedules that serve as baseline references for ongoing system monitoring and optimization efforts.

Maintenance and Technical Support Programs

Comprehensive maintenance support programs significantly impact the long-term reliability and cost-effectiveness of your oxidation blower investment. Leading suppliers offer structured maintenance programs including preventive maintenance schedules, spare parts availability guarantees, and technical support services that minimize unplanned downtime and extend equipment lifespan. These programs typically include regular inspection services, performance monitoring, and predictive maintenance recommendations based on operating data analysis.

Emergency support capabilities are crucial for maintaining continuous oxidation processes in critical applications. Reliable suppliers maintain 24/7 technical support hotlines, rapid response service teams, and strategically located parts inventories that enable quick resolution of operational issues. The availability of remote monitoring and diagnostic capabilities allows suppliers to proactively identify potential problems and recommend corrective actions before equipment failures occur.

Cost Analysis and Value Assessment

Total Cost of Ownership Evaluation

Comprehensive cost analysis extends beyond initial equipment purchase price to include operational costs, maintenance expenses, energy consumption, and expected equipment lifespan. Energy efficiency significantly impacts long-term operating costs, particularly for continuous-duty oxidation applications where blowers operate 24/7 throughout the year. High-efficiency oxidation blower designs can reduce energy consumption by 15-30% compared to standard models, resulting in substantial cost savings over equipment lifespan.

Maintenance costs vary significantly between suppliers based on equipment design complexity, parts availability, and required service intervals. Suppliers offering standardized components, extended maintenance intervals, and readily available spare parts typically provide lower total ownership costs despite potentially higher initial purchase prices. Additionally, equipment reliability directly impacts operational costs through reduced downtime, emergency repair expenses, and production losses associated with oxidation system failures.

Financial Terms and Support Options

Flexible financing options and payment terms can significantly impact project feasibility and cash flow management for oxidation blower investments. Progressive suppliers offer various financing alternatives including equipment leasing programs, extended payment terms, and performance-based contracts that align supplier compensation with equipment performance objectives. These options enable organizations to implement necessary oxidation upgrades while managing capital expenditure constraints and budget limitations.

Warranty terms and coverage scope provide important indicators of supplier confidence in their equipment quality and long-term reliability. Comprehensive warranties covering both equipment and performance guarantee protection against manufacturing defects and performance shortfalls that could impact operational effectiveness. Extended warranty options and service agreements provide additional protection and predictable maintenance costs throughout equipment lifespan.

Supplier Reputation and Track Record

Industry Experience and Project Portfolio

Evaluating supplier experience in your specific industry and application type provides valuable insights into their capability to deliver appropriate solutions for your oxidation requirements. Suppliers with extensive experience in similar applications understand the unique challenges, regulatory requirements, and performance expectations associated with your industry sector. This experience translates into better equipment recommendations, more accurate performance predictions, and reduced implementation risks.

Project portfolio review should include examination of similar installations, performance results, and customer feedback from comparable applications. Successful suppliers readily provide case studies, reference installations, and customer testimonials that demonstrate their track record of delivering reliable oxidation solutions. Site visits to existing installations can provide firsthand observation of equipment performance and operational characteristics under real-world conditions.

Customer References and Market Reputation

Customer references provide unbiased insights into supplier performance, service quality, and long-term partnership effectiveness beyond marketing materials and sales presentations. Contacting existing customers directly allows assessment of supplier responsiveness, technical support quality, and equipment reliability based on actual operational experience. These conversations often reveal important details about supplier strengths and potential weaknesses not apparent during initial evaluation processes.

Market reputation assessment should include industry recognition, professional certifications, and participation in relevant trade organizations and technical committees. Suppliers actively engaged in industry development through research initiatives, technical publications, and standard development activities typically demonstrate superior technical expertise and commitment to advancing oxidation technology solutions.

FAQ

What factors should I prioritize when selecting an oxidation blower supplier?

Prioritize technical expertise relevant to your specific application, proven track record in similar installations, comprehensive support services including installation and maintenance, and total cost of ownership rather than just initial purchase price. Additionally, consider supplier stability, parts availability, and emergency support capabilities to ensure long-term operational reliability.

How important is energy efficiency in oxidation blower selection?

Energy efficiency is critically important for continuous-duty oxidation applications due to substantial long-term operating cost impacts. High-efficiency models can reduce energy consumption by 15-30% compared to standard designs, resulting in significant cost savings over equipment lifespan that often justify higher initial investment costs within 2-3 years of operation.

What maintenance support should I expect from a quality supplier?

Quality suppliers provide comprehensive maintenance programs including preventive maintenance schedules, spare parts availability guarantees, technical support hotlines, and emergency service capabilities. Look for suppliers offering predictive maintenance technologies, remote monitoring options, and structured service agreements that minimize unplanned downtime and extend equipment lifespan.

How can I verify supplier claims about equipment performance and reliability?

Request detailed performance data, customer references from similar applications, and arrange site visits to existing installations for firsthand performance observation. Review warranty terms, certification documentation, and ask for third-party performance verification reports. Additionally, contact existing customers directly to discuss their experience with equipment performance and supplier support quality.