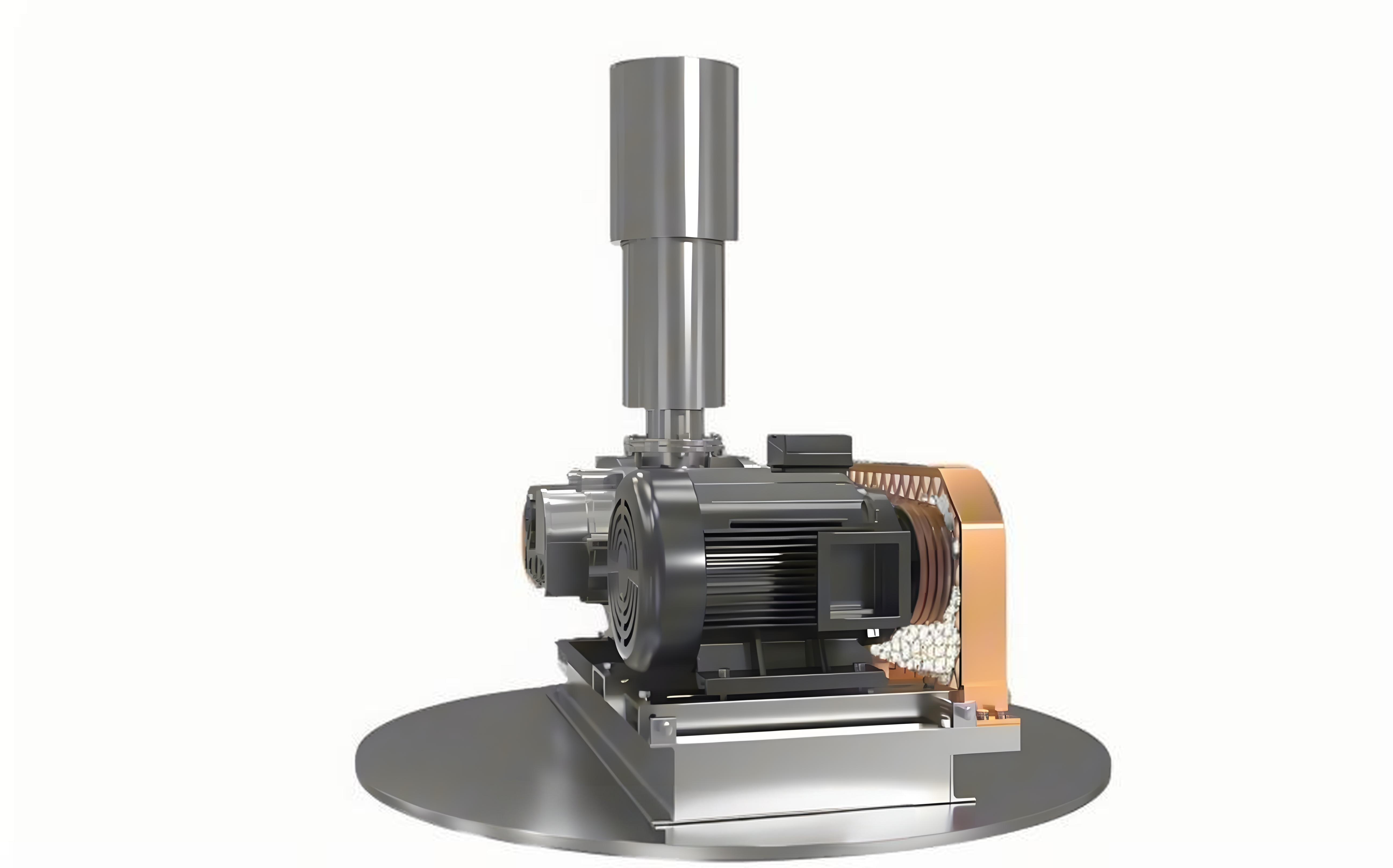

Оптимізація енергії в промислових вакуумних системах стає вкрай важливою, оскільки виробники прагнуть знизити експлуатаційні витрати, зберігаючи пікову продуктивність. вакуумний насос-дутьошка roots є однією з найпоширеніших технологій у виробництві, хімічній промисловості та системах обробки матеріалів. Розуміння способів максимізації енергоефективності цих систем вимагає комплексного підходу, що включає правильний підбір потужності, протоколи обслуговування та найкращі практики експлуатації. Сучасні об'єкти, які використовують родинний дихач вакуумні насосні системи, можуть досягти суттєвого економлення енергії шляхом стратегічного застосування оптимізації, що не лише зменшує споживання електроенергії, але також подовжує термін служби обладнання та підвищує загальну надійність системи.

Розуміння динаміки енергоспоживання вакуумних насосів типу Рутс

Основи споживання потужності

Споживання енергії системою вакуумного насоса золотникового типу залежить перш за все від різниці тиску, вимог до витрати та експлуатаційної ефективності. Ці об'ємні машини споживають потужність, пропорційну до об’єму перекачуваного газу та необхідного ступеня стиснення. Розуміння цього взаємозв’язку має вирішальне значення для оптимізації, оскільки навіть невеликі покращення ефективності з часом можуть призвести до суттєвого енергозбереження. Потужність зростає експоненціально, коли система досягає більш глибоких рівнів вакууму, тому дуже важливо працювати лише на тому рівні вакууму, який необхідний для конкретного застосування.

Варіації температири суттєво впливають на енергоспоживання у роботі вакуумних насосів з об'ємним стисненням газу. Коли температура газу зростає під час стиснення, об'ємна ефективність знижується, що вимагає більше енергії для підтримання потрібного рівня вакууму. Утворення тепла всередині системи створює каскадний ефект, при якому підвищена температура призводить до зниження ефективності, що, у свою чергу, генерує ще більше тепла. Належне термокерування шляхом застосування адекватних систем охолодження та монтування температури стає необхідним для підтримання оптимальних енергетичних показників протягом тривалих періодів роботи.

Характеристики навантаження системи

Різні застосування висувають різні вимоги до систем вакуумних насосів з кореневим нагнітачем, і розуміння цих характеристик навантаження є основоположним для оптимізації енергоспоживання. У застосунках з тривалим режимом роботи потрібно забезпечити оптимальну ефективність у сталому стані, тоді як у переривчастому режимі важливими є швидкий запуск і оперативна реакція. Характеристики технологічного газу, зокрема вологість, вміст частинок і хімічний склад, впливають як на енерговитрати, так і на потребу в обслуговуванні системи.

Змінні умови навантаження створюють унікальні виклики та можливості для оптимізації енергії. Багато промислових процесів зазнають коливань попиту на вакуум протягом свого робочого циклу, і традиційні системи вакуумних насосів з кореневим компресором постійної швидкості часто працюють неефективно в періоди зниженого попиту. Впровадження стратегій керування, чутливих до навантаження, може суттєво підвищити загальну ефективність системи, адаптуючи продуктивність компресора до реальних потреб процесу замість підтримки постійної максимальної потужності.

Стратегічне визначення розміру та оптимізація вибору

Принципи узгодження потужності

Правильний підбір розміру є основою енергоефективної роботи вакуумного насоса з кореневим нагнітачем. Надмірно великі системи витрачають енергію, працюючи в умовах зниженої ефективності, тоді як надто малі системи не можуть задовольнити вимоги процесу й часто працюють безперервно на максимальних потужностях. Оптимальна стратегія підбору передбачає ретельний аналіз фактичних вимог процесу, включаючи періоди пікового попиту, типові умови експлуатації та допустимі коливання рівня вакууму. Цей аналіз має враховувати втрати в системі, зокрема втрати тиску в трубопроводах і рівні витоків, що впливають на реальні вимоги до відкачування.

Кілька менших вакуумних насосів з кореневим компресором, що працюють паралельно, часто забезпечують кращу енергоефективність порівняно з одним великим агрегатом, особливо в застосунках із змінними режимами навантаження. Такий модульний підхід дозволяє ступінчасто включати обладнання залежно від фактичних потреб, утримуючи окремі агрегати у режимах, близьких до їхньої максимальної ефективності. Можливість вимикати зайві агрегати в періоди низького попиту може призвести до значної економії енергії, зберігаючи при цьому резервування системи для критично важливих застосунків.

Критерії вибору технології

Сучасні технології вакуумних насосів з корінчастим нагнітачем пропонують різні покращення ефективності порівняно з традиційними конструкціями. Сучасні профілі роторів, висока точність виготовлення та покращені системи ущільнення забезпечують вищий об'ємний ККД та знижене енергоспоживання. У процесі вибору необхідно оцінювати ці технологічні переваги на тлі конкретних вимог застосування та очікуваного строку служби, щоб визначити оптимальну економічну ефективність сучасних функцій.

Можливості інтеграції з сучасними системами керування є ще одним важливим критерієм вибору для оптимізації енергоспоживання. Системи, оснащені частотними перетворювачами, інтелектуальними засобами моніторингу та функціями автоматичного керування, забезпечують можливості динамічної оптимізації, яких не можуть забезпечити традиційні агрегати з постійною швидкістю. Витрати на впровадження таких сучасних систем керування зазвичай окупаються за рахунок економії енергії та скорочення потреб у технічному обслуговуванні протягом строку експлуатації системи.

Впровадження частотного перетворювача

Переваги регулювання швидкості

Перетворювачі частоти пропонують один із найефективніших методів оптимізації споживання енергії в системах вакуумних насосів з рутс-дозаторами. Завдяки точному керуванню швидкістю двигуна, ПЧ дозволяють системі підлаштовувати свій вихід під реальні технологічні потреби, замість використання механічного дроселювання чи байпасних методів, що призводять до втрат енергії. Економія енергії від впровадження ПЧ може бути значною, особливо в застосунках із суттєвими коливаннями навантаження протягом робочого циклу.

Зв'язок між зниженням швидкості та економією енергії в системах вакуумних насосів з рутс-дозаторами підпорядковується відомим законам подібності, згідно з якими споживана потужність зменшується приблизно пропорційно кубу зниження швидкості. Це означає, що навіть невелике зниження швидкості може призвести до значної економії енергії. Наприклад, зниження робочої швидкості на двадцять відсотків може забезпечити економію енергії, що наближається до п'ятдесяти відсотків, що робить впровадження ПЧ надзвичайно привабливим для застосунків із змінним навантаженням.

Розробка стратегії керування

Ефективна реалізація ЧРП вимагає складних стратегій керування, які адекватно реагують на вимоги процесу та забезпечують стабільність системи. Системи керування на основі тиску автоматично регулюють швидкість вакуумного насоса з рутс-дозатором для підтримання заданих рівнів вакууму, забезпечуючи оптимальну енергоефективність при виконанні виробничих вимог. Складні алгоритми керування можуть включати прогнозуючі елементи, які передбачають зміни попиту та проактивно коригують роботу системи, а не реагують на події ретроспективно.

Інтеграція з системами управління енергоспоживанням на всьому об'єкті дозволяє координовано оптимізувати роботу декількох установок вакуумних насосів з кореневим нагнітачем. Такий комплексний підхід може оптимізувати режим споживання енергії, планувати технічне обслуговування в періоди низького попиту та узгоджувати послідовності запуску для мінімізації плати за пікове навантаження. Дані, отримані через ці інтегровані системи, надають цінну інформацію для постійного вдосконалення стратегій енергоефективності.

Моніторинг системи та аналітика продуктивності

Реальне відстеження продуктивності

Сучасні системи монітування забезпечують безпрецедентний огляд характеристик продуктивності вакуумного насоса з кореневим дуетером, що дозволяє приймати оптимізаційні рішення на основі даних. Відстеження в реальному часі ключових параметрів, таких як споживання електроенергії, рівні вакууму, швидкості потоку та температурні профілі, дозволяє операторам виявлювати неефективність і постійно оптимізувати роботу системи. Ці системи монітування можуть виявляти поступове погіршення продуктивності, яке іншими способами може залишитися непоміченим до того моменту, коли вже відбувається значне витрачання енергії.

Платформи передового аналізу можуть корелювати кілька експлуатаційних параметрів, щоб виявити можливості оптимізації, які можуть бути незрозумілими при простому моніторингу параметрів. Алгоритми машинного навчання можуть аналізувати історичні дані про продуктивність, щоб прогнозувати оптимальні умови роботи для різних технологічних вимог, автоматично налаштовуючи роботу системи для підтримки максимальної ефективності. Ця передбачувальна здатність є значним кроком вперед порівняно з традиційними стратегіями реагування на події та експлуатації.

Інтеграція передбачувального обслуговування

Енергоефективність систем вакуумних насосів рутс тісно пов’язана з механічним станом та станом технічного обслуговування. Програми передбачуваного технічного обслуговування, які контролюють рівні вібрації, температуру підшипників та інші показники стану механічного здоров’я, можуть запобігти погіршенню ефективності до того, як це вплине на споживання енергії. Своєчасне виявлення ознак зносу, проблем з вирівнюванням або погіршенням ущільнень дозволяє проводити проактивне обслуговування, що забезпечує оптимальну ефективність протягом усього життєвого циклу обладнання.

Інтеграція моніторингу споживання енергії з системами передбачуваного технічного обслуговування створює комплексний підхід до оптимізації системи. Незвичні зростання споживання енергії можуть слугувати ранніми попередженнями про потенційні механічні несправності, тоді як контроль стану механічних компонентів дозволяє прогнозувати майбутнє погіршення ефективності. Такий інтегрований підхід максимізує як енергоефективність, так і надійність обладнання, одночасно мінімізуючи витрати на обслуговування та незаплановані простої.

Експлуатаційні найкращі практики для енергоефективності

Стратегії оптимізації процесу

Оптимізація процесів, що обслуговуються вакуумними насосними системами з об'ємними повітряними насосами, часто забезпечує більш значну економію енергії, ніж оптимізація самих повітряних насосів. Зменшення проникнення повітря в процес, мінімізація непотрібних рівнів вакууму та оптимізація часу процесу можуть суттєво знизити енергетичні вимоги, які встановлює вакуумна система. Регулярна оцінка вимог процесу забезпечує роботу системи вакуумного насоса з об'ємним повітряним насосом лише за необхідністю та на мінімальному рівні вакууму, необхідному для ефективного функціонування процесу.

Впровадження змін у процеси, що зменшують навантаження газу на вакуумну систему, може забезпечити значну економію енергії. Це може включати вдосконалення систем ущільнення, зниження температур процесів там, де це можливо, або впровадження систем рекуперації газу, які зменшують обсяг газу, що підлягає відкачуванню вакуумним насосом з рутс-дожерелом. Такі стратегії оптимізації процесів часто забезпечують найвищий рівень окупності інвестицій у підвищення енергоефективності.

Планування та управління навантаженням

Стратегічне планування роботи вакуумних насосів з рутс-дожерелом дозволяє оптимізувати режим споживання енергії та зменшити плату за пікове навантаження. Узгодження вакуумних операцій під час періодів знижених тарифів на електроенергію може забезпечити значну економію, тоді як рознесення в часі процедур запуску допомагає мінімізувати плату за пікове навантаження. Сучасні системи планування можуть автоматично оптимізувати час роботи виходячи з тарифів на енергію, виробничих вимог та доступності обладнання.

Балансування навантаження між кількома системами вакуумних насосів з роторними нагнітачами дозволяє загалом оптимізувати споживання енергії, зберігаючи при цьому надійність процесу. Цей підхід полягає у автоматичному розподілі навантаження між наявними блоками для підтримки роботи кожної системи вблизу точки її максимальної ефективності. Складні системи керування можуть враховувати такі фактори, як криві ефективності окремих блоків, стан обслуговування та вартість енергії, аби визначити оптимальні стратегії розподілу навантаження.

Сучасні системи рекуперації тепла та охолодження

Використання відновленого тепла

Тепло, що виникає під час стиснення вакуумного насоса з кореневим дутилем, представляє можливість для відновлення енергії в багатьох застосуваннях. Системи рекуперації тепла можуть вловлювати цю теплову енергію для використання у опаленні об'єктів, підігріві процесів або інших теплових застосувань. Ефективність рекуперації тепла залежить від досягнутих рівнів температири та наявності відповідних теплових навантажень у об'єкті, проте успішне впровадження може забезпечити значну загальну економію енергії.

Сучасні конструкції теплообмінників, спеціально розроблені для застосувань вакуумних насосів з кореневим дутилем, максимізують ефективність рекуперації тепла, зберігаючи оптимальну продуктивність дутиля. Ці системи можуть відновлювати значну кількість теплової енергії, яка іншим чином була б втрачена, що сприяє загальній енергоефективності об'єкту. Економічні переваги систем рекуперації тепла часто виправдовують їх витрати через зниження витрат на опалення та покращення загального використання енергії.

Оптимізація системи охолодження

Ефективна система охолодження має важливе значення для підтримання енергоефективності при роботі вакуумних насосів з об'ємними насосами типу рутс. Надмірне охолодження призводить до витрати енергії, тоді як недостатнє охолодження знижує ефективність і може пошкодити обладнання. Оптимізовані системи охолодження підтримують температуру в ідеальному діапазоні для максимальної ефективності, одночасно зводячи до мінімуму споживання енергії на охолодження. Вентилятори охолодження зі змінною швидкістю та інтелігентні системи регулювання температури можуть автоматично налаштовувати потужність охолодження відповідно до теплового навантаження.

Інтеграція систем охолодження з системами опалення, вентиляції та кондицювання (HVAC) об'єкта може забезпечити додаткові можливості оптимізації. Узгоджена робота систем охолодження вакуумних насосів рутс з кліматичним контролем будівлі дозволяє оптимізувати загальне споживання енергії об'єкта. У холодну погоду відпрацьоване тепло з системи насосів може використовуватися для опалення об'єкта, тоді як у теплу погоду оптимізовані стратегії охолодження можуть звести до мінімуму навантаження на системи кондицювання об'єкта.

ЧаП

Який типовий потенціал економії енергії при оптимізації системи вакуумного насоса з об'ємним дожиманням?

Економія енергії від оптимізації вакуумного насоса з об'ємним дожиманням зазвичай становить від п'ятнадцяти до сорока відсотків, залежно від поточної ефективності системи та заходів оптимізації, що були впроваджені. Встановлення частотно-регульованого приводу найчастіше забезпечує найбільший окремий джерело економії, особливо в застосуваннях із змінними навантаженнями. Комплексні програми оптимізації, які вирішують питання розміру, керування, обслуговування та експлуатаційних практик, можуть досягти економії на верхньому рівні цього діапазону, одночасно поліпшуючи надійність та продуктивність системи.

Яким чином належне обслуговування впливає на споживання енергії у системах вакуумного насоса з об'ємним дожиманням?

Належне технічне обслуговування має суттєвий вплив на споживання енергії, оскільки добре обслуговувані системи зазвичай споживають на десять-двадцять відсотків менше енергії порівняно з системами, що мають поганий стан. Регулярне обслуговування запобігає погіршенню ефективності, викликаному зносом, невирівнюванням, погіршенням стану ущільнень та накопиченням забруднень. Програми передбачуваного обслуговування, які вирішують проблеми до того, як вони впливають на продуктивність, дозволяють підтримувати оптимальну ефективність протягом усього життєвого циклу обладнання, а також зменшують кількість несподіваних збоїв і пов'язані з цим втрати енергії.

Чи можна ефективно оптимізувати старі системи вакуумних насосів з кореневим нагнітачем для підвищення енергоефективності?

Системи вакуумних насосів з корінням старішого типу часто можна значно покращити за допомогою заходів доопрацювання, хоча економічна ефективність залежить від терміну експлуатації та стану системи. Встановлення частотного регулювання, покращені системи керування та удосконалені системи моніторингу можуть забезпечити суттєве поліпшення навіть на старішому обладнанні. Однак дуже старі системи можуть більше виграти від заміни на сучасні високоефективні установки, особливо якщо інакше потрібне проведення великого ремонту чи реконструкції.

Яку роль відіграє розмір системи у оптимізації енергоефективності установок вакуумних насосів з корінням?

Розмірування системи є основою енергоефективної роботи, оскільки системи з неправильним розміром не можуть досягти оптимальної ефективності незалежно від інших заходів оптимізації. Системи великого розміру витрачають енергію, працюючи зі зниженим рівнем ефективності, тим часом як системи малого розміру працюють безперервно на максимальній потужності і можуть мати труднощі з задоволенням технологічних потреб. Аналіз правильного розміру повинен враховувати реальні технологічні потреби, втрати в системі та майбутні потреби потужності, щоб визначити оптимальну конфігурацію для довгострокової енергоефективності.

Зміст

- Розуміння динаміки енергоспоживання вакуумних насосів типу Рутс

- Стратегічне визначення розміру та оптимізація вибору

- Впровадження частотного перетворювача

- Моніторинг системи та аналітика продуктивності

- Експлуатаційні найкращі практики для енергоефективності

- Сучасні системи рекуперації тепла та охолодження

-

ЧаП

- Який типовий потенціал економії енергії при оптимізації системи вакуумного насоса з об'ємним дожиманням?

- Яким чином належне обслуговування впливає на споживання енергії у системах вакуумного насоса з об'ємним дожиманням?

- Чи можна ефективно оптимізувати старі системи вакуумних насосів з кореневим нагнітачем для підвищення енергоефективності?

- Яку роль відіграє розмір системи у оптимізації енергоефективності установок вакуумних насосів з корінням?