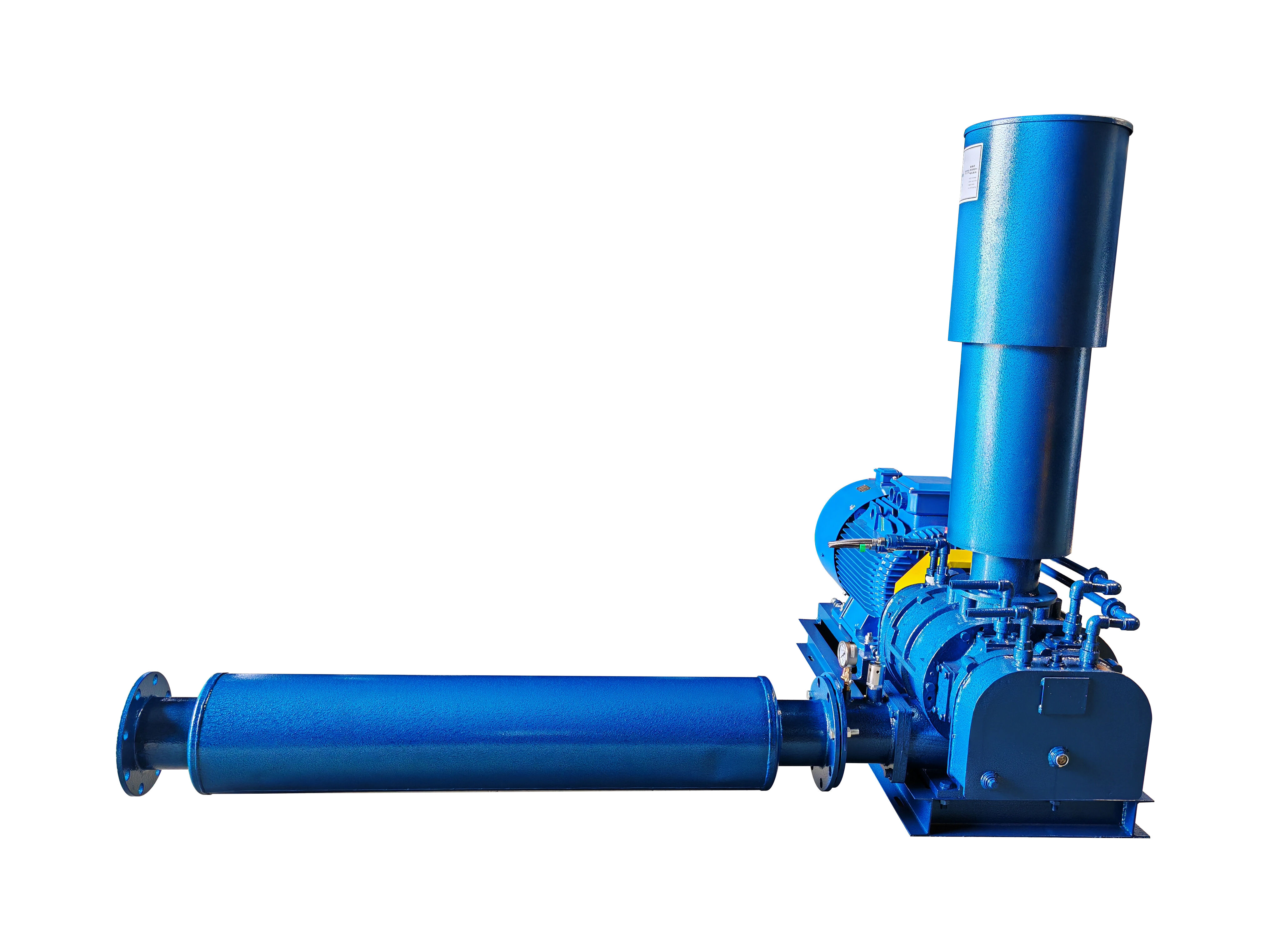

3 lobe roots blower

The 3 lobe roots blower represents a significant advancement in industrial air compression technology, offering enhanced performance and reliability compared to traditional two-lobe designs. This innovative machine consists of two counter-rotating rotors with three lobes each, precisely synchronized through timing gears. The unique three-lobe configuration creates a more efficient compression process by reducing pulsation and providing smoother airflow. Operating on the positive displacement principle, it captures air at the inlet, compresses it through rotation, and discharges it at higher pressure. The system achieves compression without internal lubrication, ensuring oil-free operation critical for sensitive applications. These blowers typically operate at speeds between 1000 to 5000 RPM, delivering consistent airflow rates and pressure levels up to 15 PSI. The design incorporates precision-machined rotors with minimal clearances, advanced sealing systems, and robust bearings to maintain operational efficiency. Common applications include wastewater treatment, pneumatic conveying, food processing, and various industrial processes requiring clean, compressed air. The 3 lobe roots blower's durability, reliability, and efficient performance make it an essential component in modern industrial operations.