aeration blower types

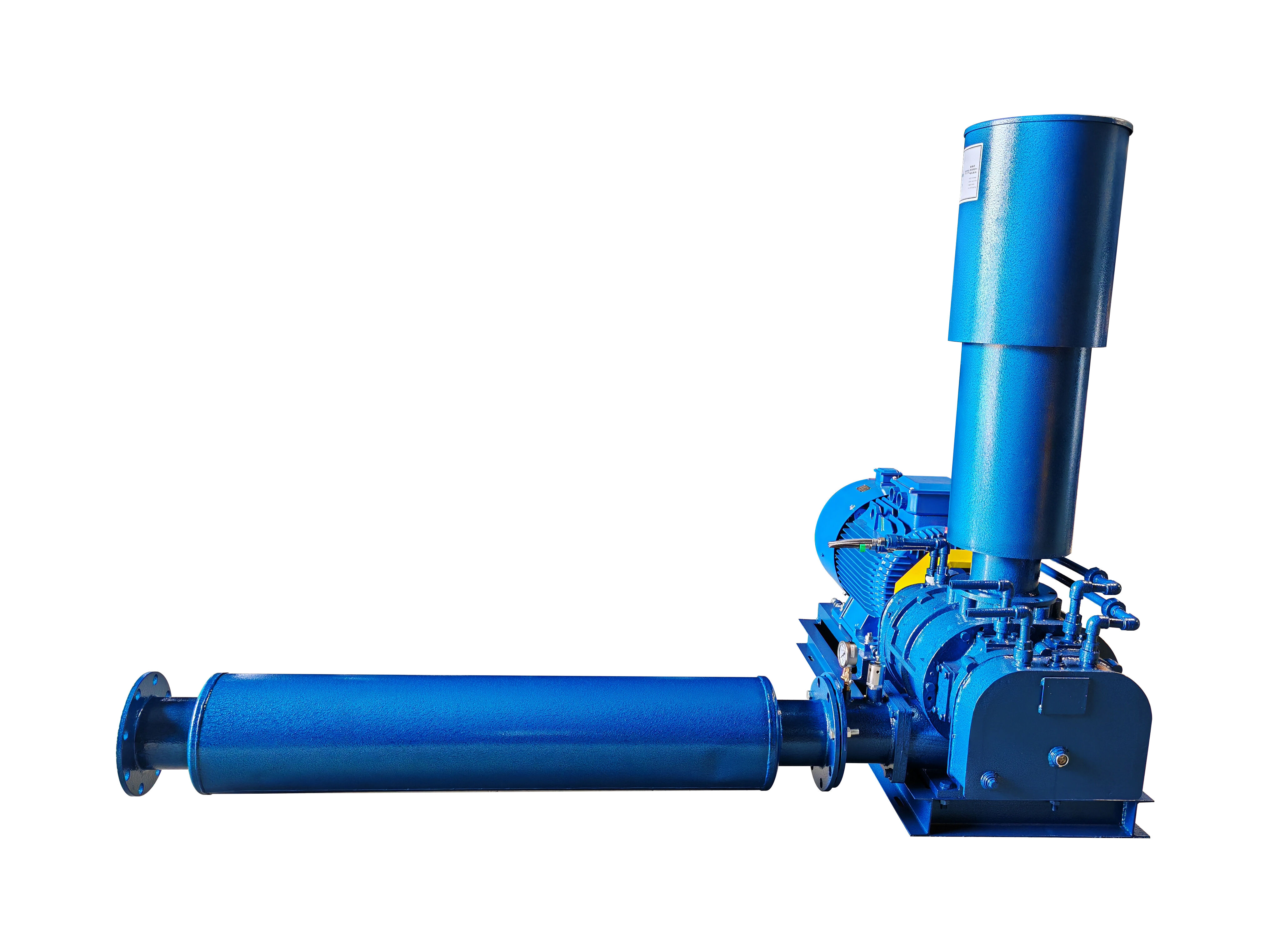

Aeration blowers represent essential equipment in wastewater treatment and industrial processes, delivering vital air supply for various applications. These sophisticated devices come in several types, including positive displacement blowers, centrifugal blowers, and turbo blowers, each engineered to meet specific operational requirements. Positive displacement blowers operate by trapping air between rotating lobes and forcing it through the system, offering consistent airflow across varying pressure conditions. Centrifugal blowers utilize high-speed impellers to accelerate air radially, converting velocity into pressure energy. Turbo blowers, the most advanced category, employ advanced aerodynamic principles and high-speed motors to deliver exceptional efficiency. These systems incorporate modern control technologies, including variable frequency drives (VFD) and smart monitoring systems, enabling precise airflow regulation and energy optimization. The applications span across municipal wastewater treatment, industrial fermentation, pneumatic conveying, and various manufacturing processes. Modern aeration blowers feature sophisticated designs that prioritize energy efficiency, operational reliability, and reduced maintenance requirements, making them indispensable in contemporary industrial operations.