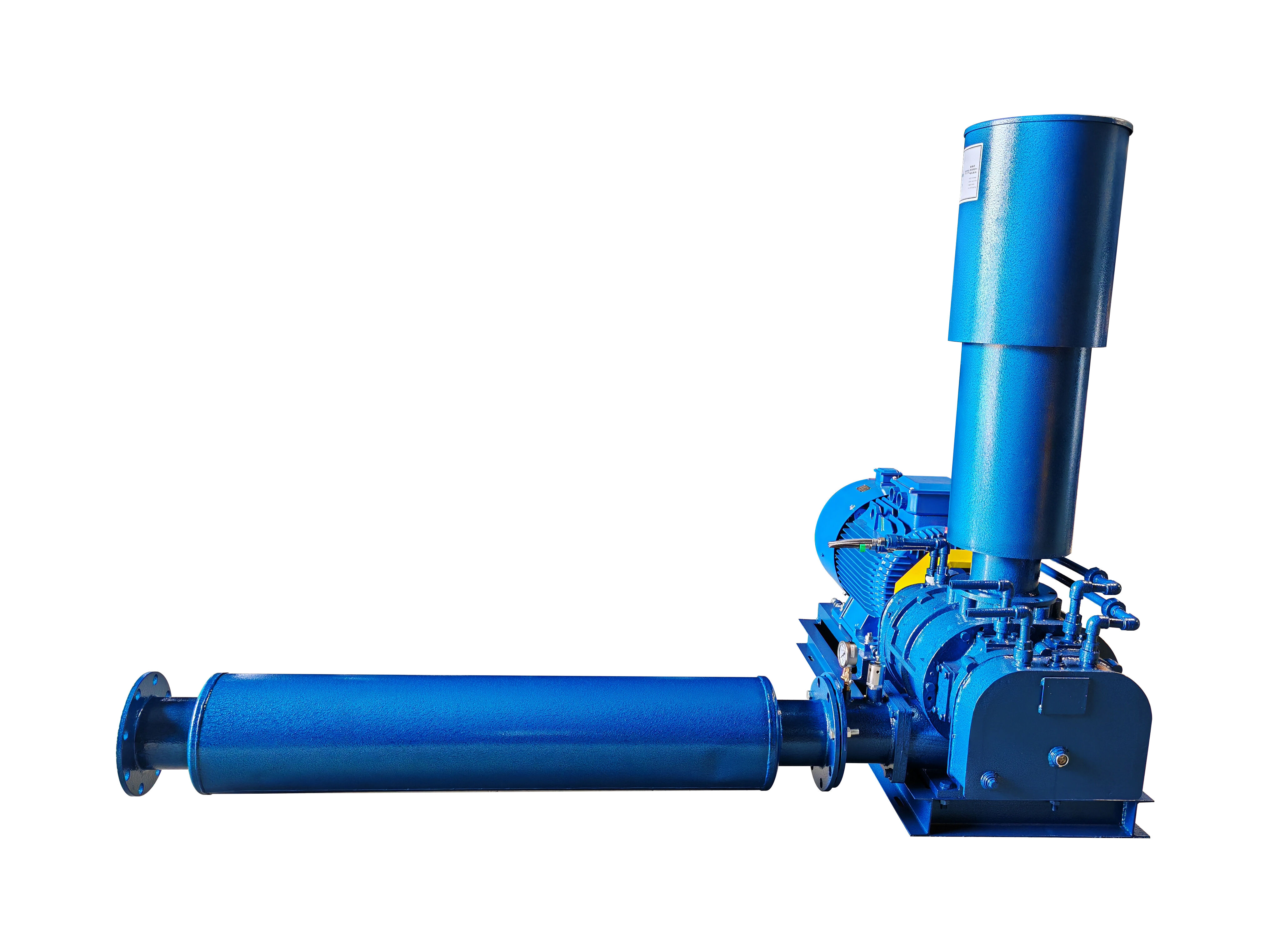

durable directly connected roots blower

The durable directly connected roots blower represents a significant advancement in industrial air compression technology. This robust system features a direct coupling mechanism between the motor and the blower unit, eliminating the need for belt drives or complex transmission systems. The design incorporates precision-engineered rotors that operate in perfect synchronization, creating a consistent and reliable air flow. Operating at speeds ranging from 600 to 3600 RPM, these blowers deliver pressure capabilities of up to 15 PSI, making them ideal for various industrial applications. The system's construction utilizes high-grade materials, including cast iron casings and hardened steel rotors, ensuring exceptional durability and longevity. Advanced sealing technology prevents air leakage while minimizing power loss, resulting in superior operational efficiency. The direct connection design significantly reduces maintenance requirements and improves overall system reliability by eliminating common wear points associated with traditional belt-driven systems. These blowers excel in applications requiring continuous operation, such as wastewater treatment, pneumatic conveying, and industrial process aeration.