aeration blowers wastewater treatment

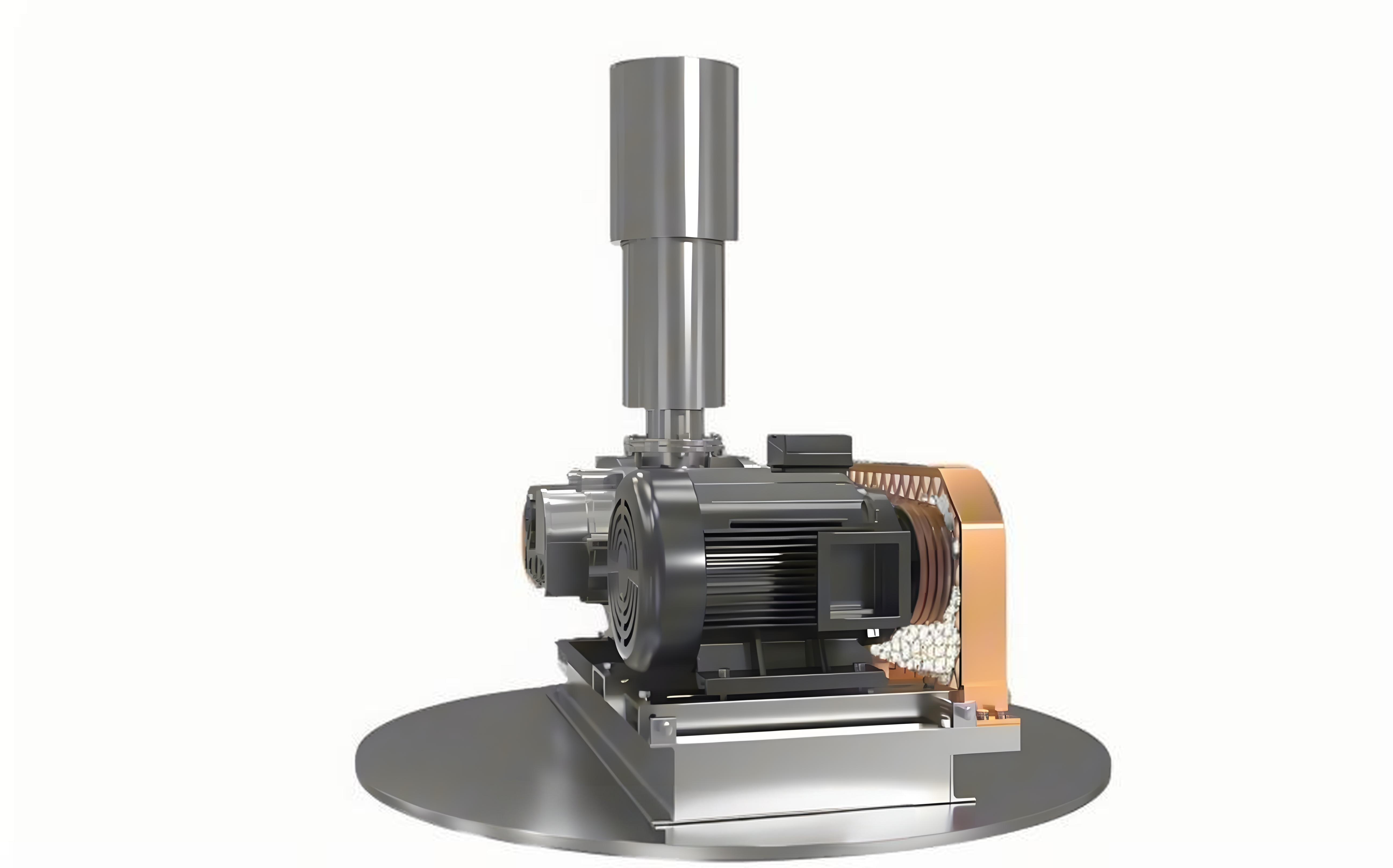

Aeration blowers are critical components in wastewater treatment systems, serving as the primary mechanism for introducing oxygen into the treatment process. These sophisticated devices inject air into wastewater, facilitating the growth of aerobic bacteria that break down organic matter and pollutants. Modern aeration blowers utilize advanced technologies such as variable frequency drives and precision control systems to maintain optimal dissolved oxygen levels throughout the treatment process. The system typically consists of high-efficiency motors, specialized impellers, and smart monitoring equipment that work in concert to deliver the right amount of air at the right time. These blowers can be configured in various arrangements, including positive displacement, centrifugal, and hybrid designs, each suited to specific treatment requirements and facility sizes. The technology has evolved to incorporate energy-efficient features, noise reduction capabilities, and automated operation systems that ensure consistent performance while minimizing operational costs. Aeration blowers play a vital role in both municipal and industrial wastewater treatment facilities, supporting biological treatment processes, nitrogen removal, and overall water quality improvement.