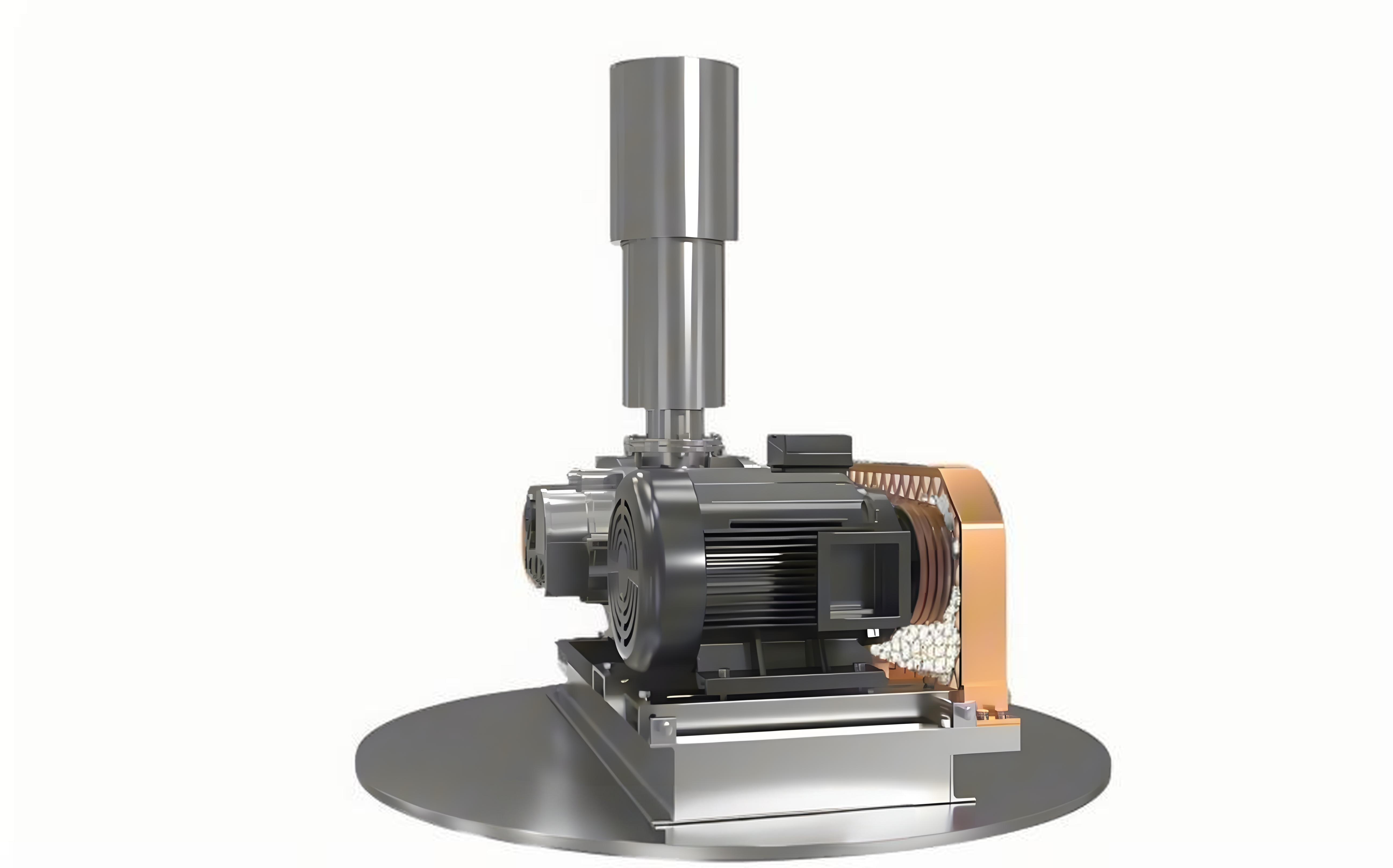

sewage treatment equipment

Sewage treatment equipment represents a critical infrastructure component designed to process and purify wastewater from various sources, making it safe for environmental discharge or reuse. This sophisticated system employs multiple stages of treatment, including primary separation, biological processing, and advanced filtration mechanisms. The equipment typically consists of screening units, settling tanks, biological reactors, and disinfection systems working in harmony to remove contaminants, pollutants, and harmful substances from wastewater. Modern sewage treatment equipment incorporates advanced automation features, real-time monitoring capabilities, and energy-efficient components that optimize operational performance while reducing environmental impact. The technology utilizes both physical and biological processes to break down organic matter, remove suspended solids, and eliminate harmful pathogens. These systems are scalable and can be customized to meet specific treatment requirements, from small-scale residential applications to large municipal facilities. The equipment's modular design allows for easy maintenance, upgrades, and expansion as treatment needs evolve. Additionally, many current systems include resource recovery capabilities, enabling the extraction of valuable materials and energy from the treatment process, contributing to a more sustainable waste management approach.