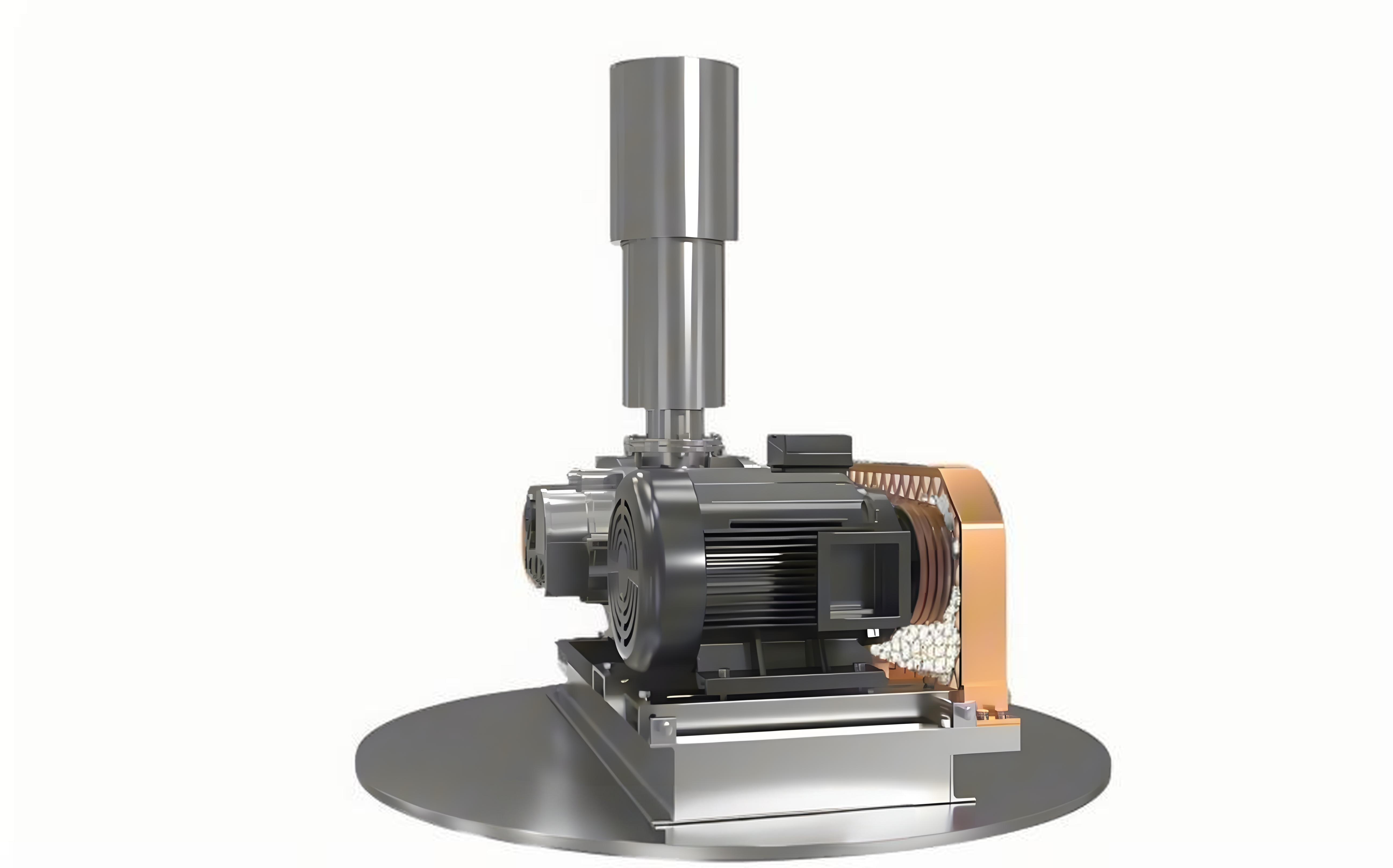

air blower for sewage treatment plant

Air blowers for sewage treatment plants are essential mechanical devices that play a crucial role in the wastewater treatment process. These sophisticated machines are designed to supply compressed air into aeration tanks, facilitating the biological breakdown of organic matter through aerobic bacteria. The primary function involves delivering a consistent flow of air bubbles that promote oxygen transfer and maintain optimal dissolved oxygen levels necessary for microorganisms to effectively treat wastewater. Modern air blowers incorporate advanced technologies such as variable frequency drives (VFD) for energy-efficient operation and precise airflow control. These systems typically operate using either positive displacement or centrifugal mechanisms, each offering specific advantages depending on the application requirements. The equipment is engineered to withstand continuous operation in demanding environments, featuring robust construction materials and protective coatings that ensure longevity. Additionally, these blowers are equipped with sophisticated monitoring systems that provide real-time performance data, enabling operators to maintain optimal treatment conditions while minimizing energy consumption. Their applications extend beyond conventional sewage treatment, serving various industrial wastewater treatment processes, aquaculture facilities, and environmental remediation projects.