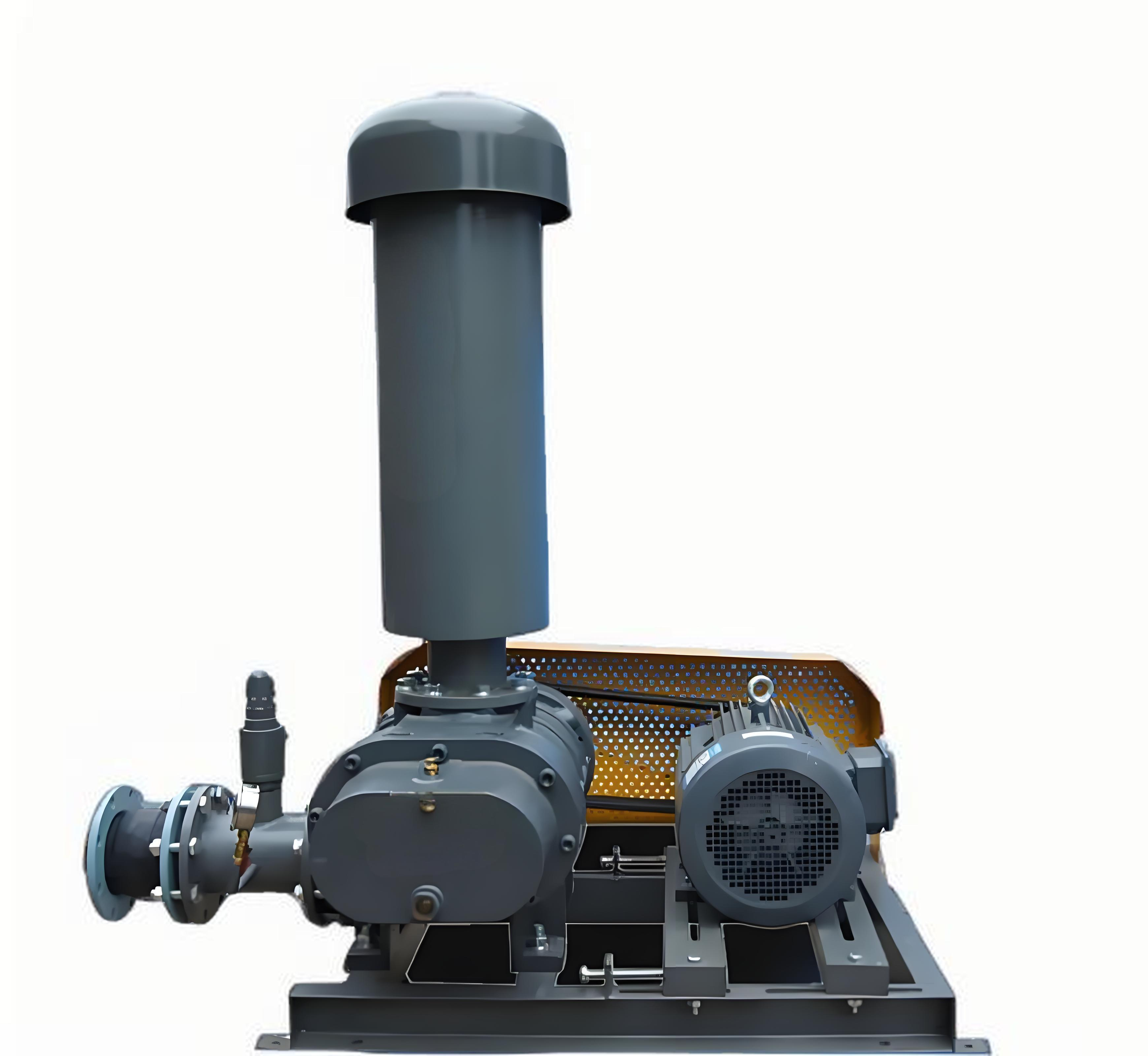

centrifugal air blower

A centrifugal air blower is a sophisticated mechanical device that harnesses centrifugal force to move air and gases efficiently. At its core, the system consists of a rotating impeller housed within a specially designed casing. As the impeller spins at high speeds, it creates a powerful centrifugal force that draws air in through the central inlet and propels it outward to the casing's periphery. The air is then compressed and discharged at high velocity through the outlet. This dynamic process enables the blower to handle large volumes of air while maintaining consistent pressure levels. The technology incorporates advanced aerodynamic principles in its design, featuring precisely engineered blade profiles that optimize airflow patterns and maximize efficiency. Modern centrifugal air blowers are equipped with variable speed controls, allowing for precise adjustment of airflow rates to meet specific application requirements. These versatile systems find extensive applications across various industries, including manufacturing, wastewater treatment, pneumatic conveying, and HVAC systems. They excel in applications requiring continuous operation, high-pressure capabilities, and reliable performance under demanding conditions. The robust construction and efficient operation make them ideal for both industrial processes and commercial ventilation systems.