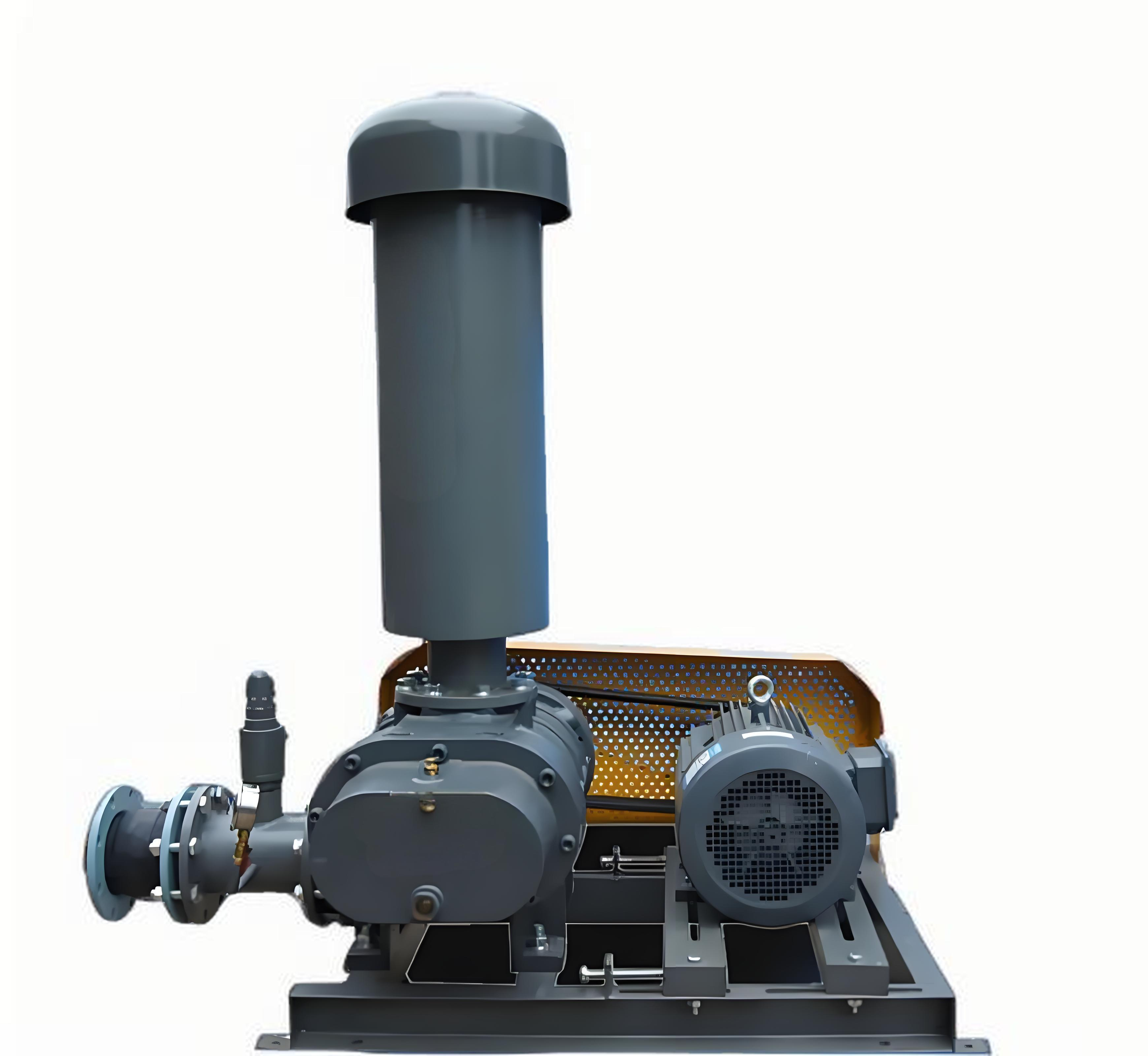

roots blower vacuum pump supplier

A roots blower vacuum pump supplier is a specialized provider of essential industrial equipment that combines innovative technology with reliable performance. These suppliers offer comprehensive solutions for various vacuum and pressure applications across multiple industries. The roots blower vacuum pump system consists of two synchronized rotors that create vacuum conditions through a precise mechanical process. These suppliers typically provide a range of models with varying capabilities, from small-scale operations to large industrial applications. Their products feature advanced engineering designs that ensure optimal efficiency, reduced energy consumption, and minimal maintenance requirements. The technical specifications often include customizable pressure ranges, flow rates, and motor powers to meet specific customer needs. Modern roots blower vacuum pumps from reputable suppliers incorporate features such as noise reduction technology, thermal protection systems, and smart monitoring capabilities. These suppliers also offer expertise in system integration, helping customers select and implement the most suitable vacuum solutions for their specific applications. The equipment finds extensive use in industries such as chemical processing, wastewater treatment, pneumatic conveying, and food packaging. Professional suppliers maintain strict quality control measures and provide comprehensive after-sales support, including maintenance services, spare parts, and technical consultation.