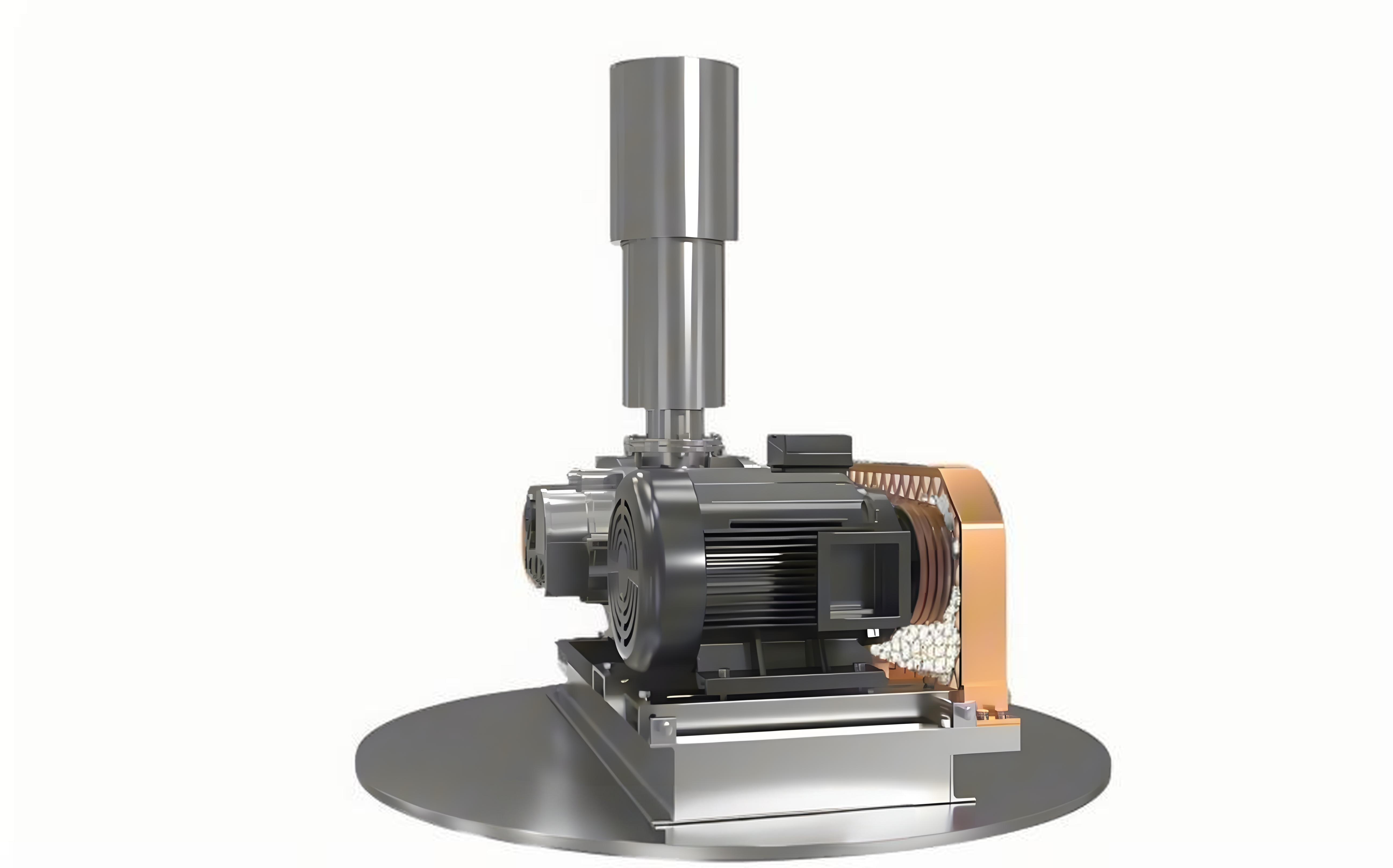

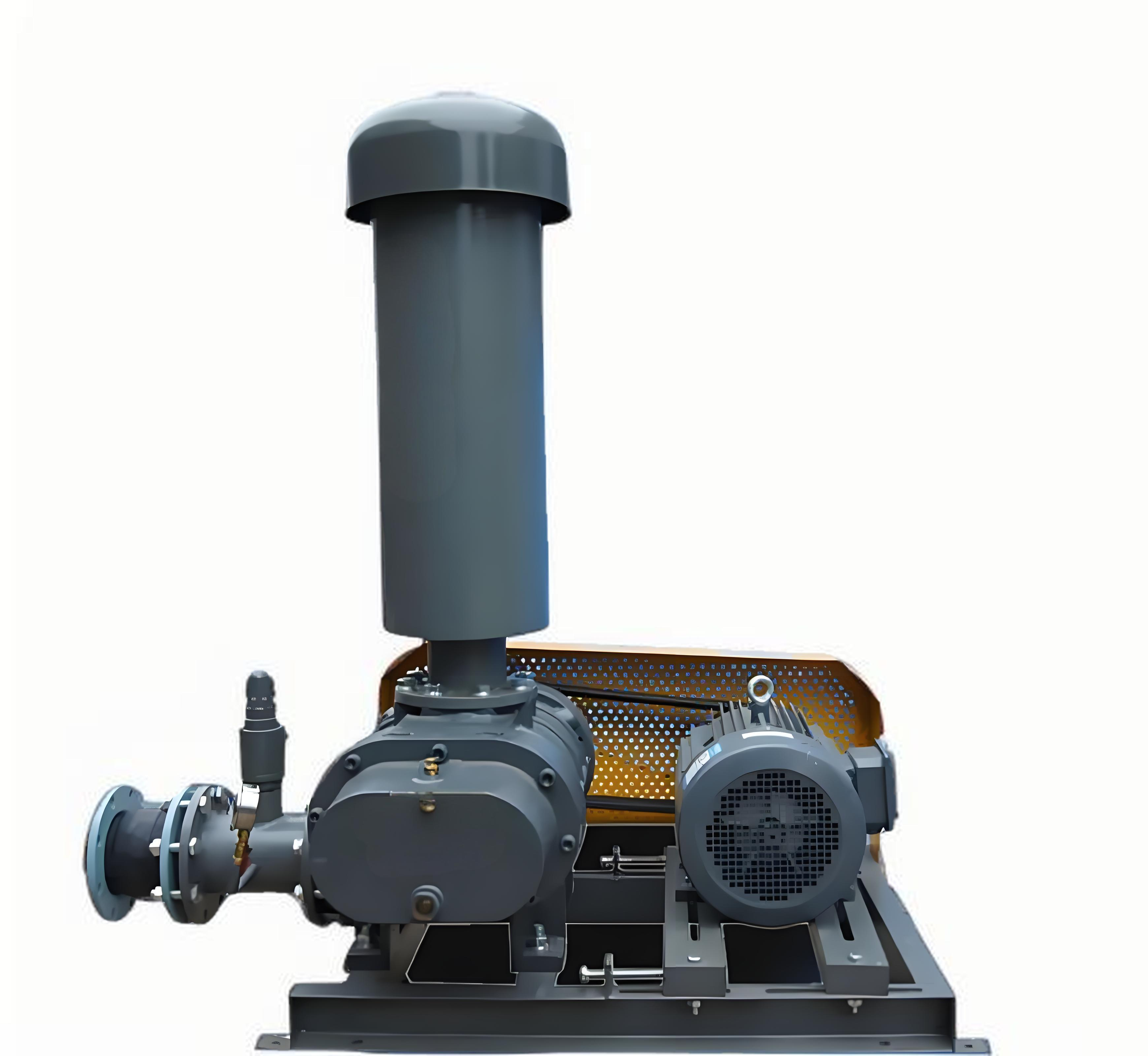

roots vacuum blower

The roots vacuum blower represents a pioneering advancement in industrial vacuum technology, operating on the principle of positive displacement to create powerful suction forces. This sophisticated device consists of two symmetrical rotors that rotate in opposite directions within a specially designed housing, creating a continuous flow of air or gas. The precision-engineered lobes, typically featuring a figure-eight cross-section, work in perfect synchronization to trap and transport air molecules from the inlet to the outlet port. Operating at speeds ranging from 500 to 3600 RPM, these blowers can achieve impressive vacuum levels while maintaining exceptional efficiency. The system's robust construction, typically incorporating hardened steel rotors and precision bearings, ensures reliable performance in demanding industrial environments. Modern roots vacuum blowers often integrate advanced features such as variable frequency drives for speed control, temperature monitoring systems, and noise reduction technology. These units excel in applications requiring consistent vacuum levels, making them indispensable in processes such as material handling, pneumatic conveying, and industrial drying systems. The technology's versatility allows for both single-stage and multi-stage configurations, enabling customization based on specific vacuum requirements.