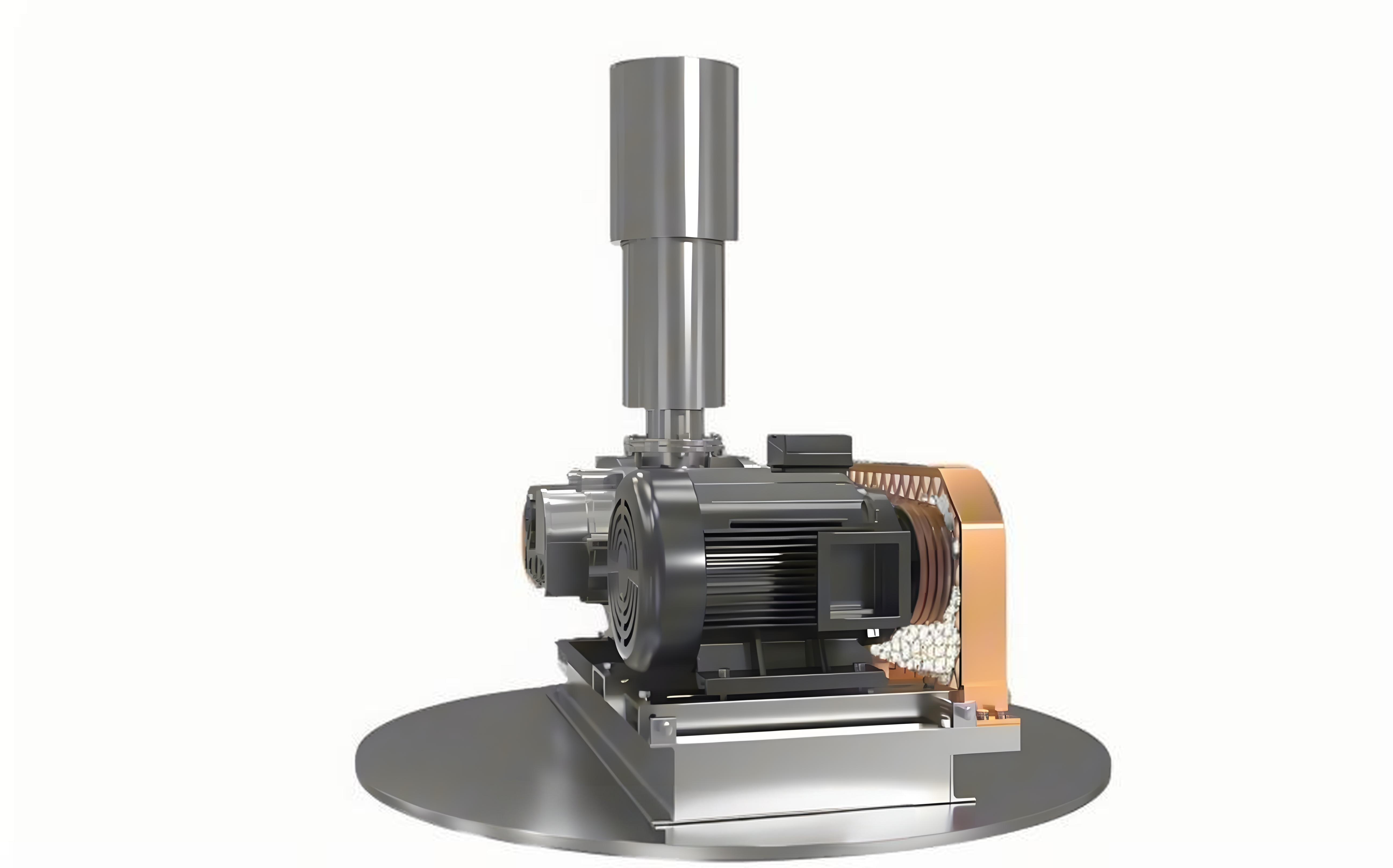

roots blower pump

A roots blower pump is a highly efficient mechanical device that operates on the positive displacement principle to move air or gas. This sophisticated piece of equipment consists of two counter-rotating lobes housed within a casing, creating a reliable and consistent flow of air or gas. The pump operates by trapping air between the lobes and the housing, then displacing it to create either pressure or vacuum conditions. The precision-engineered rotors, typically featuring a figure-eight cross-section, rotate in opposite directions without making contact, ensuring minimal wear and maintenance requirements. These pumps are capable of handling large volumes of air while maintaining consistent pressure levels, making them ideal for various industrial applications. The roots blower pump's design allows for oil-free operation, which is crucial in applications requiring clean air output. Modern roots blowers incorporate advanced materials and coating technologies that enhance their durability and performance while reducing operational noise. These pumps can achieve high compression ratios and operate efficiently across a wide range of speeds, providing flexibility in various applications from wastewater treatment to pneumatic conveying systems.