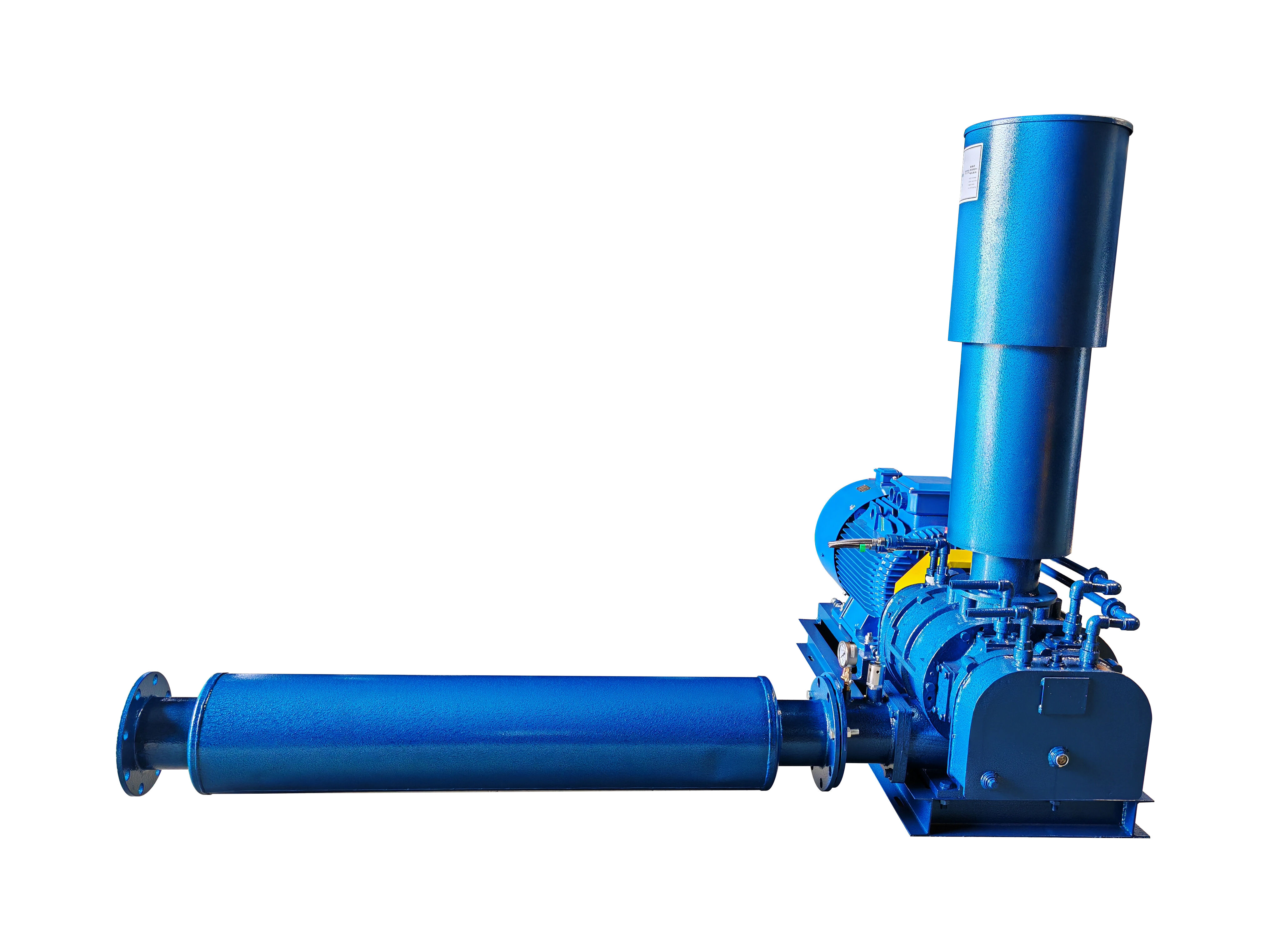

sewage treatment plant blower

A sewage treatment plant blower is an essential piece of equipment in wastewater treatment facilities, designed to provide a continuous and reliable supply of air for the biological treatment process. These blowers operate by compressing and delivering air to aeration tanks, where microorganisms break down organic matter in the wastewater. The system typically consists of a motor-driven impeller housed within a specially designed casing, capable of generating high-volume airflow at specific pressures. Modern sewage treatment plant blowers incorporate advanced technologies such as variable frequency drives (VFDs) for energy-efficient operation, sound attenuation systems for noise reduction, and precise airflow control mechanisms. They play a crucial role in maintaining optimal dissolved oxygen levels necessary for aerobic bacterial activity, which is fundamental to the wastewater treatment process. These blowers are engineered to handle continuous operation in demanding environments, featuring robust construction materials that resist corrosion and wear. The technology also includes sophisticated monitoring systems that provide real-time performance data, allowing operators to maintain optimal efficiency and prevent potential system failures.