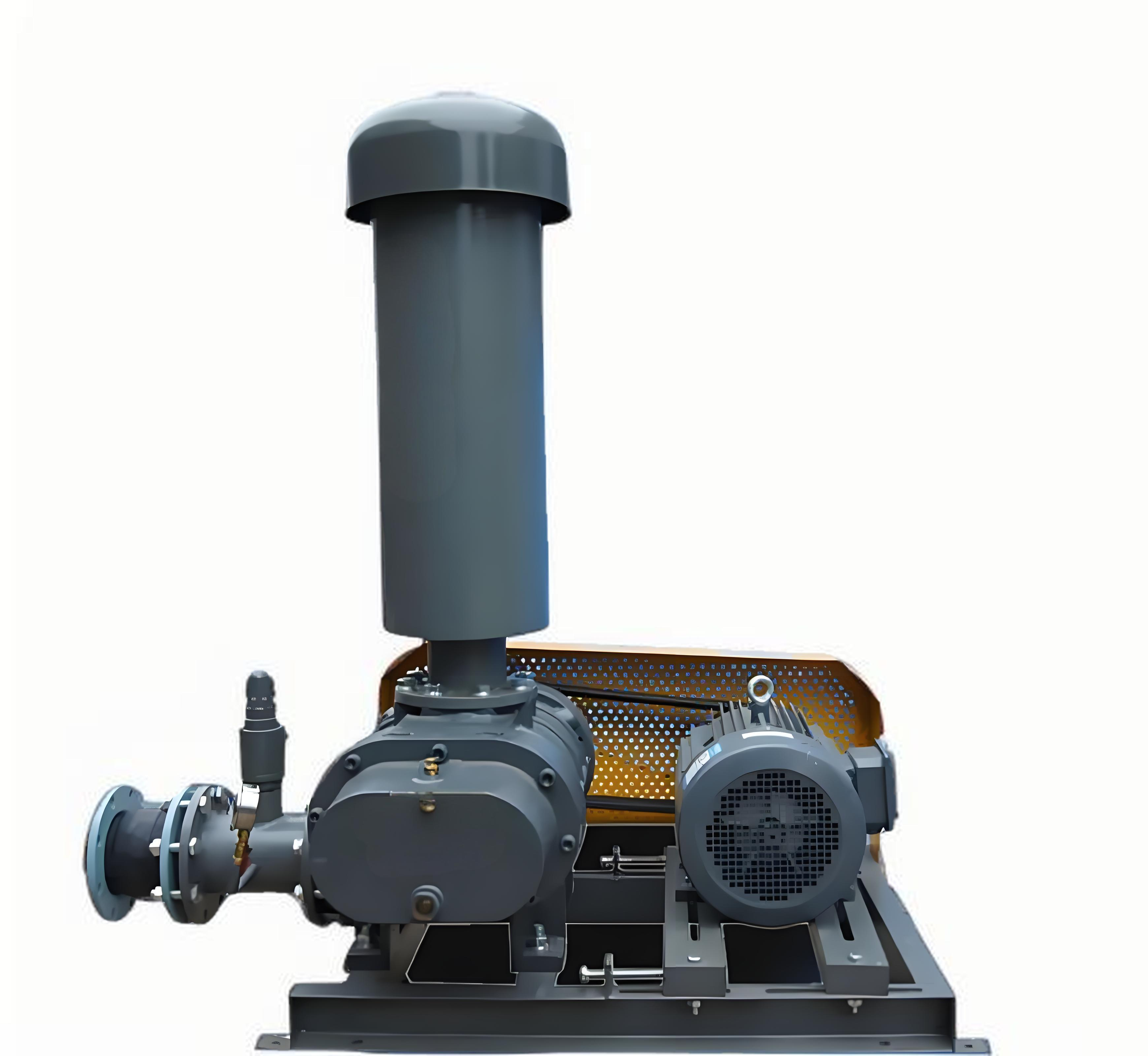

roots type pump

A Roots type pump represents a sophisticated positive displacement device that operates through the synchronized rotation of two figure-eight shaped lobes. These precisely engineered lobes rotate in opposite directions within a carefully designed housing, creating a continuous pumping action that efficiently moves gases or liquids. The pump's design allows for the creation of sealed chambers between the lobes and housing, enabling the effective transport of media from the inlet to the outlet port. Operating at speeds typically ranging from 500 to 4000 RPM, these pumps excel in applications requiring consistent flow rates and moderate vacuum levels. The robust construction features precision-machined rotors, typically manufactured from high-grade materials such as ductile iron or stainless steel, ensuring durability and reliable performance. Roots pumps are particularly valued in industrial processes for their ability to handle large volumes of gases while maintaining stable pressure differentials. Their versatility extends across various industries, including chemical processing, wastewater treatment, pneumatic conveying systems, and industrial vacuum applications. The pump's oil-free operation makes it especially suitable for processes where contamination must be avoided, such as food processing and pharmaceutical manufacturing.