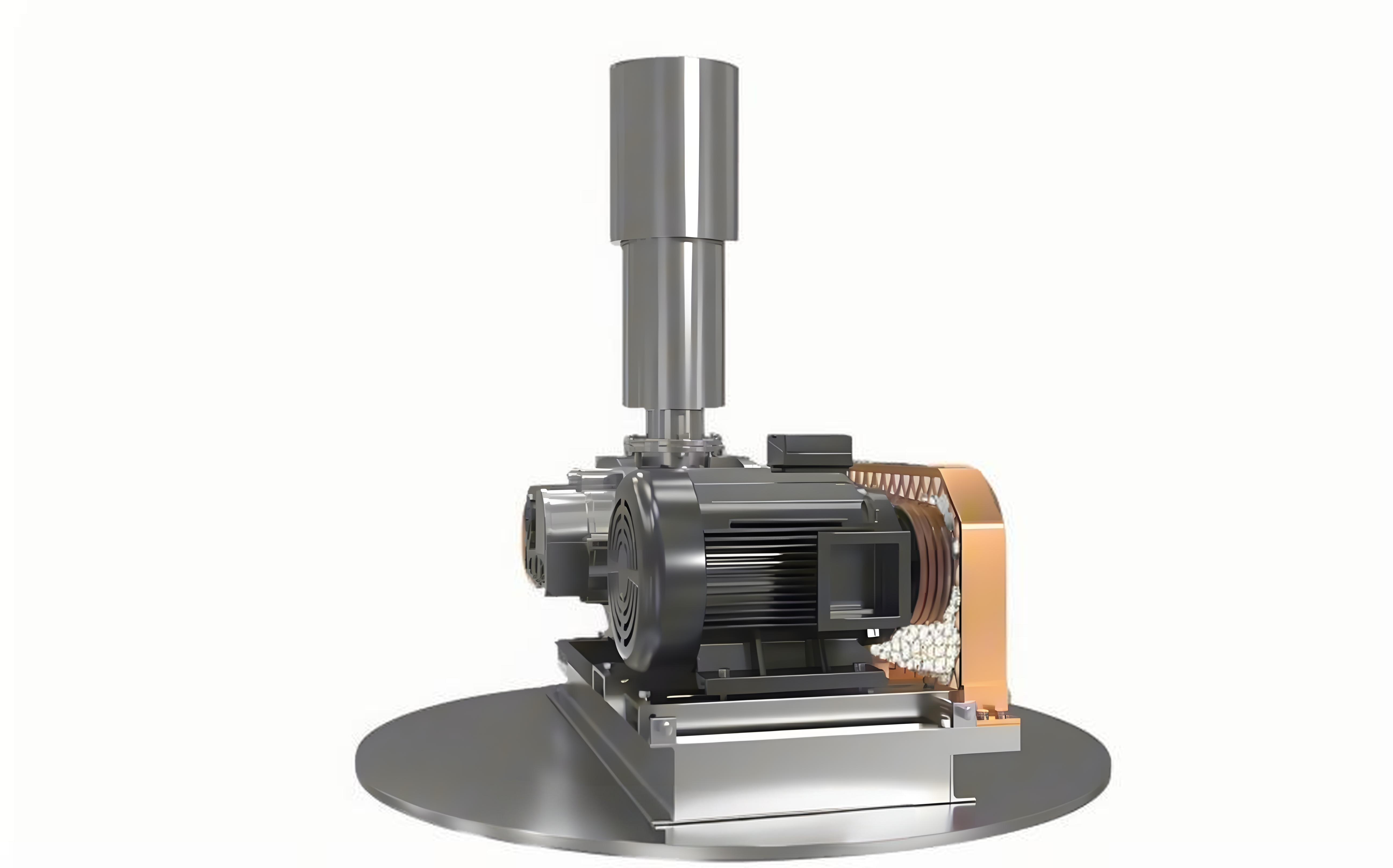

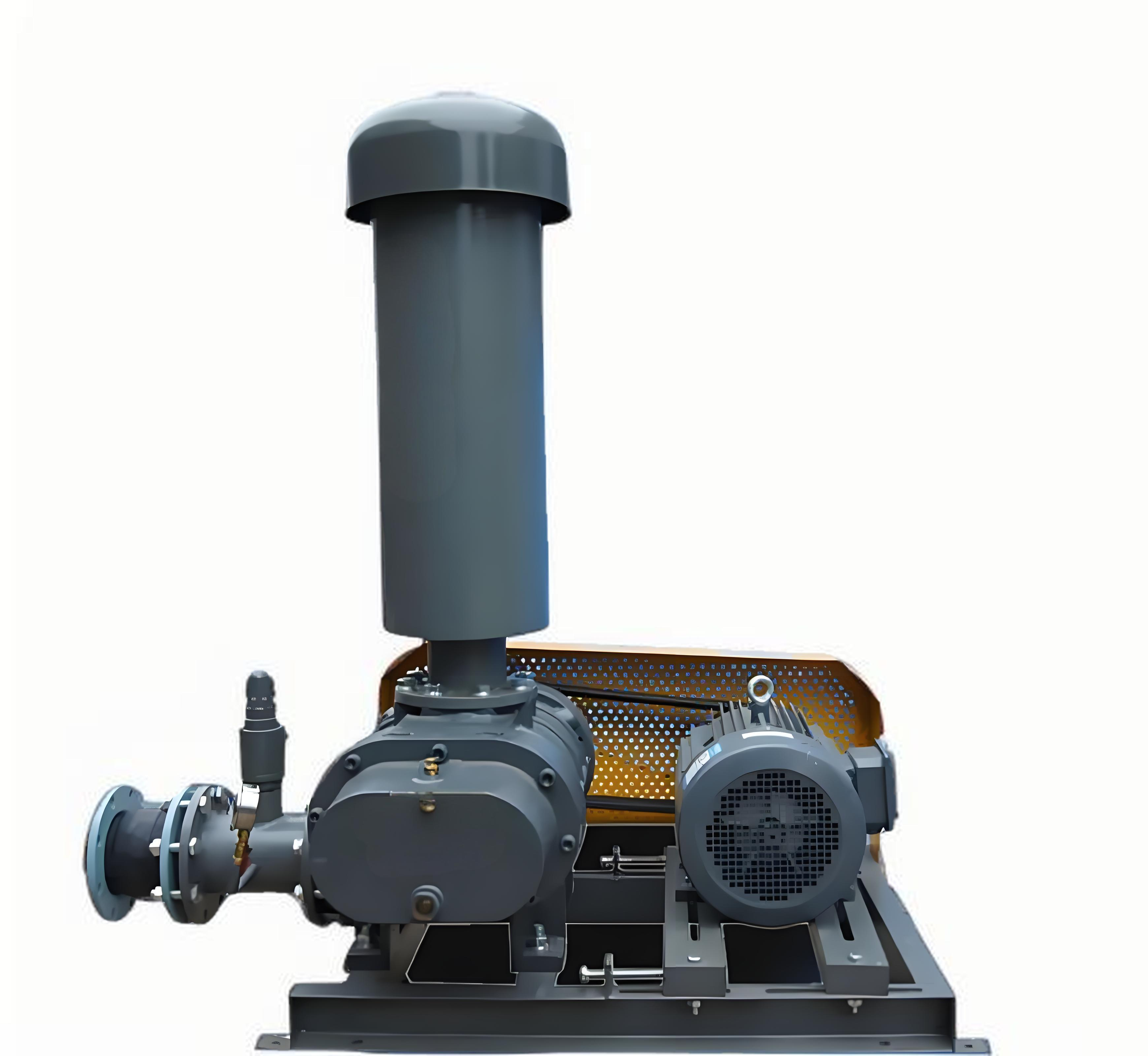

rotary blower vacuum pump

A rotary blower vacuum pump is an innovative industrial device that combines efficiency with reliability in vacuum generation. This sophisticated piece of equipment operates through a pair of counter rotating impellers that create a powerful vacuum effect by trapping and compressing air molecules. The pump's design features precision engineered lobes that rotate without contact, ensuring minimal wear and extended operational life. The system effectively maintains consistent vacuum levels through its continuous rotation mechanism, making it ideal for various industrial applications. These pumps are particularly noteworthy for their ability to handle large volumes of air while maintaining stable performance levels. The technology incorporates advanced sealing systems that prevent oil contamination, making them especially suitable for applications requiring clean operation. Operating at relatively low temperatures compared to other vacuum technologies, rotary blower vacuum pumps offer excellent energy efficiency and reduced cooling requirements. The robust construction includes high grade materials that resist wear and corrosion, ensuring reliable performance even in demanding industrial environments. These pumps are designed with serviceability in mind, featuring easily accessible components for maintenance and repair, which significantly reduces downtime and operational costs.